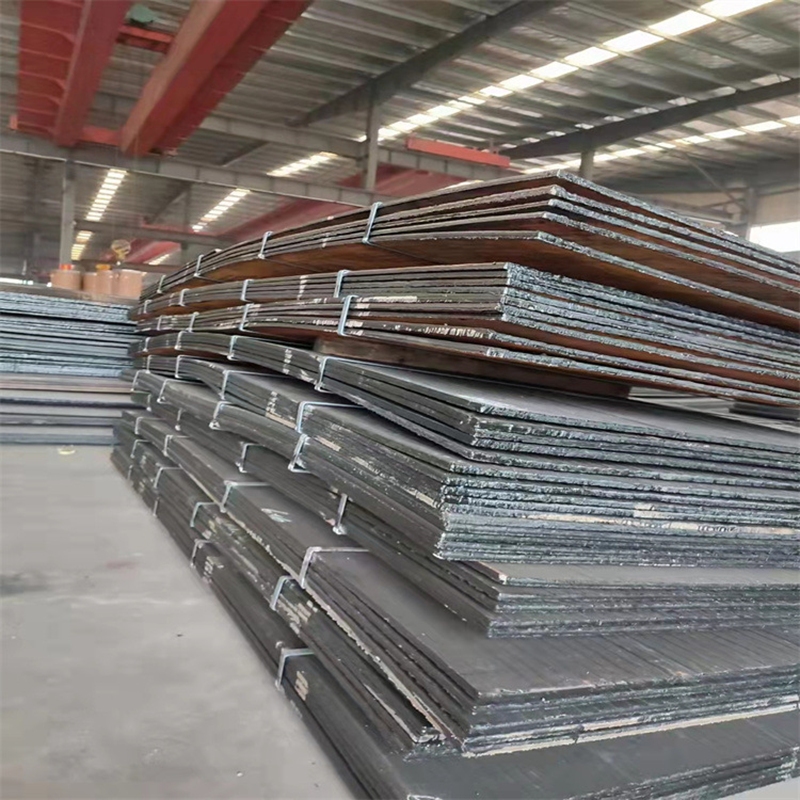

1. Uhlolojikelele lwepuleti lensimbi elingagqoki

I-Wear Resistant Steel Plate, okuyipuleti lensimbi elingagugi, umkhiqizo okhethekile wepuleti osetshenziswa ngokukhethekile ngaphansi kwezimo zokusebenza zokugqokwa kwendawo enkulu. Yakhiwe nge-low-carbon steel plate kanye ne-alloy wear-resistant layer.

Ipuleti lensimbi elingagqoki linezici zamandla aphezulu nokumelana nokugqoka okuphezulu. Ungqimba olungagugi ingxubevange ngokuvamile luwu-1/3 kuya ku-1/2 wogqinsi oluphelele. Lapho isemsebenzini, i-matrix inikeza izici eziphelele njengamandla, ukuqina kanye nepulasitiki ukuze imelane namandla angaphandle, futhi ungqimba oluqinile lwe-alloy lunikeza ukumelana nokugqoka ukuze kuhlangatshezwane nezidingo zezimo zokusebenza ezishiwo.

Kunezinhlobo ezimbalwa zamapuleti ensimbi angagugi, okuhlanganisa amapuleti ensimbi angagugi ayinhlanganisela kanye namapuleti ensimbi acishwa yingxubevange. Isibonelo, ipuleti lensimbi elingagqoki i-KN60 iwuhlobo lomkhiqizo owenziwe ngokuhlanganisa ugqinsi oluthile lwengqimba eqinile engagugiyo enokuqina okuphezulu nokumelana nokugqokwa okuhle kakhulu ebusweni bensimbi enekhabhoni ephansi noma insimbi enengxubevange ephansi enokuqina okuhle. kanye ne-plasticity ngokusebenzisa indlela yokubeka phezulu. Imingcele yezobuchwepheshe ye-KN60 yensimbi engagqoki insimbi imi kanje: ubulukhuni be-Vickers bungu-1700HV; impahla iyi-low-carbon steel base, kanti ezinye izinhlobo zama-alloys aqinile ne-niobium carbide zinganikezwa ngokuya ngezidingo. I-chromium ne-boron alloy carbides inothile; ukuqina kongqimba oluhlanganisiwe olumelana nokugqoka yi-C62-65 HRc; ubukhulu - 3 - 15 millimeters; okuqukethwe kwe-alloy eqinile kungaphezu kuka-50%; izinga lokushisa eliphezulu lokusebenza ngu-1000°C.

Ngaphezu kwalokho, i-steel-resistant steel plate 360 iwuhlobo lwamandla aphezulu kanye ne-high-wear-resistant-resistant-wear-resistant plate. Ikhiqizwa ubuchwepheshe be-prestressing futhi inamandla angcono okuqina namandla okucindezela, kanye nokumelana nokugqokwa okuhle kanye nokumelana nomthelela.

2. Ukusetshenziswa kwamapuleti ensimbi angagugi

2.1 Uhlu olubanzi lwezicelo zezimboni

Amapuleti ensimbi angagugi athola ukusetshenziswa okubanzi ezimbonini ezahlukahlukene. Embonini ye-metallurgical, asetshenziswa emishinini efana nama-crusher namabhande okuthutha, ahlala ebhekene nokuhuzuka nomthelela. Embonini yamalahle, baqashwe ezindaweni zamalahle kanye nezingxenye zemishini yezimayini ukuze bakwazi ukumelana nezimo ezinzima zokuguga. Imboni kasimende isebenzisa amapuleti ensimbi angagugi kumahhanela nasezigayweni zokugaya ukuze kuqinisekiswe impilo ende yesevisi. Embonini yamandla, asetshenziswa kuma-pulverizer amalahle kanye nezinhlelo zokubamba umlotha.

Isibonelo, i-steel-resistant steel plate 360 isetshenziswa kabanzi emikhakheni efana nezimoto, izitimela, ezondiza, i-metallurgy, imboni yamakhemikhali, imishini, i-petroleum, ugesi, ukongiwa kwamanzi, kanye nezokwakha. Ilungele izinto ezithwala imithwalo emikhulu emishinini yezimboni ngenxa yokumelana nokugqokwa kwayo okuhle kakhulu, ukumelana nomthelela, nokumelana nokugqwala.

2.2 Ukusebenza kahle kwezindleko

Uma kuqhathaniswa nezinye izinto, amapuleti ensimbi angagugi anikeza ukusebenza kwezindleko eziphezulu. Nakuba izindleko zokuqala zamapuleti ensimbi angagugi zingase zibe phezulu kancane kunezinye izinto zendabuko, ukumelana kwazo okuphakeme nokuqina kwazo kubangela ukonga okuphawulekayo ngokuhamba kwesikhathi. Isibonelo, inkampani esebenzisa amapuleti ensimbi angagugi ekukhiqizeni kwayo ingase ithole isikhathi esincishisiwe sokulungiswa nokushintshwa kwemishini, okuholela ekwandeni kokukhiqiza nokonga kwezindleko.

Ngokusho kwedatha, impilo yesevisi yamapuleti ensimbi angagqoki ngokuvamile ubude izikhathi eziningana kunezinsimbi ezivamile zensimbi. Lokhu kusho ukuthi izinkampani zinganciphisa izindleko zazo zempahla kanye nezindleko zokuyilungisa ngokuhamba kwesikhathi. Ukwengeza, ukusebenza okuhle kakhulu kwamapuleti ensimbi angagugi kunciphisa ubungozi bokungaphumeleli kwemishini nokubambezeleka kokukhiqiza, kuthuthukise nezinzuzo zabo zezomnotho. Ngenxa yalokho, izimboni ezengeziwe nabakhiqizi babonisa ukuthanda amapuleti ensimbi angagugi.

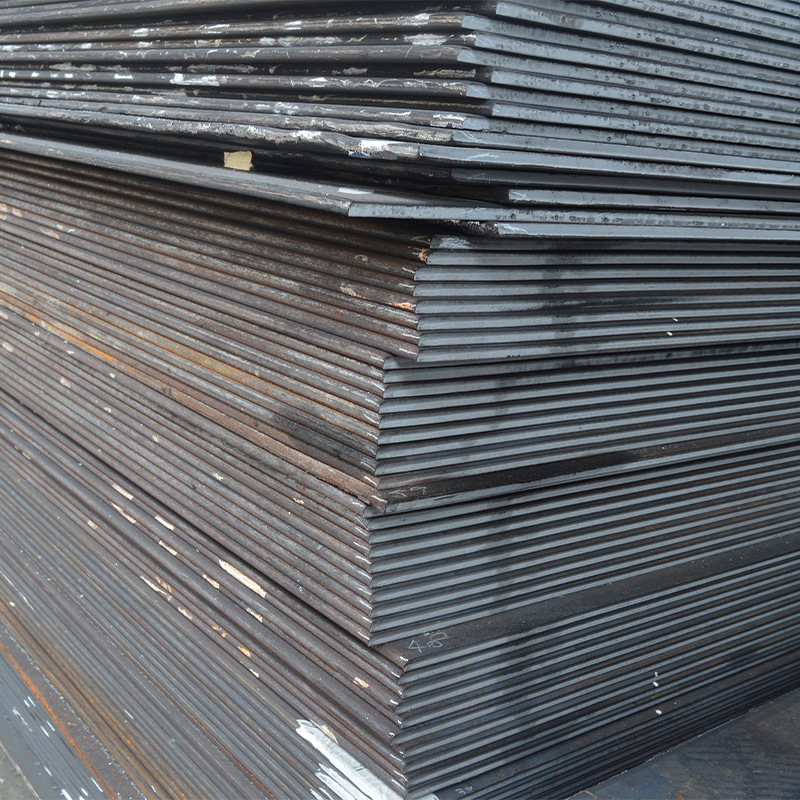

3. Ukuhlukaniswa kwezinto ezibonakalayo zamapuleti ensimbi angagugi

3.1 Izinhlobo zezinto ezijwayelekile

Amapuleti ensimbi angagugi ngokuvamile enziwa ngokubeka izendlalelo ezingagugi zengxubevange phezu kwendawo yensimbi evamile enekhabhoni ephansi noma insimbi enengxubevange ephansi. Kukhona futhi amapuleti ensimbi angagugi kanye namapuleti ensimbi acisha ingxubevange. Isibonelo, ipuleti lensimbi elingagugi elihlanganisiwe lenziwa ngokuhlanganisa ukujiya okuthile kwe-alloy-resistant layer enobunzima obuphezulu kanye nokumelana nokugqokwa okuhle kakhulu kwesisekelo sensimbi.

3.2Izinhlobo ezahlukene zezici

Ngokuyinhloko kunezinhlobo ezintathu zamapuleti ensimbi angagugi: uhlobo lwenjongo evamile, uhlobo olumelana nomthelela, kanye nohlobo olumelana nezinga lokushisa eliphezulu.

Ipuleti lensimbi elimelana nenhloso evamile linokusebenza okuzinzile futhi lifanele izimo zokugqoka ezijwayelekile. Inokumelana nokugqokwa okuhle namandla amaphakathi. Amapharamitha wobuchwepheshe angase ahlanganise izinga elithile lobulukhuni, ngokuvamile elibalelwa ku-50-60 HRC. Ukwakheka kwezinto ngokuvamile kuqukethe izakhi ezifana ne-chromium ne-manganese ukuze kuthuthukiswe ukumelana nokugqokwa. Ekusebenzeni kwayo, ingamelana nezinga elithile lokuhuzuka futhi isetshenziswa kakhulu ezimbonini ezinjengokukhiqiza imishini.

Ipuleti lensimbi elimelana nokuguga lidizayinelwe ukumelana nemithelela enzima. Inokuqina okuphezulu kanye nokumelana nomthelela omuhle kakhulu. Izinto ezisetshenziswayo ngokuvamile ziqukethe izakhi ze-alloy ezithuthukisa ukumelana nomthelela. Isibonelo, amanye amapuleti ensimbi amelana nomthelela angase abe nobulukhuni obungafinyelela ku-45-55 HRC kodwa anokumelana nomthelela ophakeme. Lolu hlobo lufanele izicelo lapho okokusebenza kungaphansi kwemithelela evamile, njengasezimbonini zezimayini nezokwakha.

Ipuleti lensimbi elimelana nezinga lokushisa eliphezulu limelana nezinga lokushisa eliphezulu. Yenziwe ngezinto ezikhethekile ze-alloy ezingagcina ukuzinza emazingeni okushisa aphezulu. Imingcele yezobuchwepheshe ingase ihlanganise izinga lokushisa eliphezulu lokusebenza elifinyelela ku-800-1200°C. Ukwakheka kwezinto ngokuvamile kuqukethe izinto ezifana ne-nickel ne-chromium ukuze kuqinisekiswe ukumelana nezinga lokushisa eliphezulu. Ekusebenzeni, isetshenziswa kabanzi ezindaweni ezishisa kakhulu njengeziko namakhilni ezimbonini ze-metallurgical kanye nosimende.

Isikhathi sokuthumela: Oct-31-2024