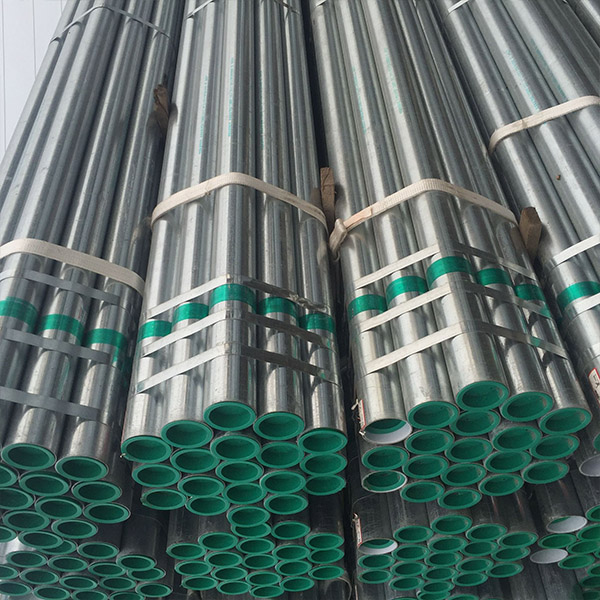

Ipayipi Lensimbi Elibandayo Elibandayo, Ipayipi Lensimbi Elishisayo-Dip

1. I-Pre-galvanized: Ipayipi lensimbi elakhiwe ngaphambilini licutshungulwa ngokuqondile kusuka emgqeni wensimbi owuketshezi oshisayo.

Isendlalelo esiphehliwe: 40-60g/sm, uma kudingeka ungqimba oluningi lwama-galvanized, lungacutshungulwa ngokuya ngokuhleleka. (Ubukhulu buyi-0.7mm-4.5mm)

2. I-Hot-dip galvanized: Ipayipi elinothayela elinediphu elishisayo linoqweqwe olushubile lwezinki kunepayipi elifakwe ngaphambili. Ipayipi lensimbi elimnyama lizocwiliswa kubhavu we-zinc ukuze lifakwe uthayela. I-zinc enamathela ingaba: 200-500g / sm

Ukugeleza kwenqubo yilokhu:ishubhu elimnyama ukuwasha-amanzi ukuwasha-ukukha-amanzi okugeza-ukucwiliswa-aid-omisa-ashisayo dip galvanizing-ukufuthela kwangaphandle-ukufuthela kwangaphakathi-umoya ukupholisa-amanzi ukupholisa -Pasivation-amanzi ukugeza-ukuhlola-isisindo-isitoreji.

1. Ukwakheka kwamakhemikhali namakhemikhali

Ibanga kanye nokwakheka kwamakhemikhali ensimbi yamapayipi ensimbi kufanele kuhambisane nebanga kanye nokwakheka kwamakhemikhali ensimbi yamapayipi amnyama njengoba kucaciswe ku-GB/T3091.

2. Indlela yokukhiqiza

Indlela yokukhiqiza yepayipi elimnyama (i-welding yesithando somlilo noma i-welding kagesi) ikhethwa ngumkhiqizi. I-hot-dip galvanizing isetshenziselwa ukuvuthela.

3. Imicu namapayipi ahlangene

(A) Emapayipini ensimbi athathiwe alethwe ngemicu, izintambo kufanele zenziwe ngomshini ngemva kokufaka uthayela. Uchungechunge kufanele luhambisane nemithetho ye-YB 822.

(B) Izihlanganisi zamapayipi ensimbi kufanele zihambisane ne-YB 238; amalunga epayipi lensimbi elithambile elithambile kufanele ahambisane ne-YB 230.

4. Izakhiwo zikamshini Izakhiwo zokuwumshini zamapayipi ensimbi ngaphambi kokuvuthwa kufanele zihlangabezane nezidingo ze-GB 3091.

5. Ukufana kwesendlalelo se-galvanized Ipayipi lensimbi elakhiwe kufanele lihlolwe ukufana kongqimba oluvunyiwe. Isampula yepayipi yensimbi akufanele iphenduke ibe bomvu (umbala ohlanganiswe ngethusi) ngemva kokucwiliswa kusixazululo se-copper sulfate izikhathi ezi-5 ezilandelanayo.

6. Ukuhlolwa kokugoba okubandayo Ipayipi lensimbi eliwuthayela elinobubanzi obungadluli ku-50mm kufanele lihlolwe ngokugoba okubandayo. I-engeli yokugoba ingu-90°, futhi i-radius egobayo iphinda izikhathi ezingu-8 ububanzi bangaphandle. Akukho ukugcwalisa ngesikhathi sokuhlolwa, futhi i-weld yesampula kufanele ibekwe ngaphandle noma engxenyeni engenhla yesiqondiso sokugoba. Ngemuva kokuhlolwa, akufanele kube nokuqhekeka nokuxebuka kwesendlalelo se-zinc kusampula.

7. Ukuhlolwa kwengcindezi yamanzi Ukuhlolwa kwengcindezi yamanzi kufanele kwenziwe ku-clarinet. Ukutholwa kwephutha lamanje kwe-Eddy nakho kungasetshenziswa esikhundleni sokuhlolwa kwengcindezi yamanzi. Ingcindezi yokuhlola noma usayizi wesampula yokuqhathanisa yokuhlolwa kwamanje kwe-eddy izohlangabezana nezimfuneko ze-GB 3092. Izakhiwo ze-mechanical zensimbi ziyinkomba ebalulekile yokuqinisekisa ukusebenza kokugcina kokusetshenziswa (izakhiwo zemishini) yensimbi.

I-Shandong Jinbaicheng Metal Material Co., Ltd. itholakala eShandong, isizinda sokukhiqiza amapayipi ashiselwe ngobukhulu emhlabeni. Ngemva kweminyaka yokusebenza kanzima, kuye kwasungulwa indlela yokuthuthukisa ukutshalwa kwezimali okuhlukahlukene. Ngokuhambisana nezidingo zemboni entsha, sinikeza ukudlala okuphelele kuzinzuzo zethu ukuze sifinyelele isikali, ukwakheka, kanye nekhwalithi. Ukuthuthukiswa okuphelele kwezinzuzo.

Sisebenza ngokukhethekile ekuthengiseni amapayipi ensimbi, amapayipi ensimbi ashisayo, amapayipi angenamthungo,. Ngemuva kweminyaka eminingana yentuthuko, sesisungule isikhathi eside

Sebenzisana namakhasimende asuka emazweni angaphezu kwangu-70 emhlabeni jikelele, okuhlanganisa i-Canada, Australia, Singapore, Thailand, South Korea, Vietnam, Mexico, Chile, Peru, ne-New Zealand. Umphumela wonyaka ungamathani ayi-700,000.

Indlela yokuxhuma ipayipi lensimbi: intambo, ishiselwe.

Ukuxhumana kwe-groove

(1) Ukuqhekeka kwe-roll groove weld

1. Hlelisa izimbambo zokushisela odongeni lwangaphakathi lwengxenye ye-pressure groove yenozzle ukuze unciphise ukumelana komsele.

2, Lungisa i-axis yepayipi lensimbi kanye nemishini yokugenca, futhi udinga ipayipi lensimbi kanye nemishini yokugenca ukuze kube izinga.

3. Lungisa isivinini sokucindezela i-groove, futhi isikhathi sokwenza i-groove asikwazi ukudlula umgomo, sebenzisa amandla ngokulinganayo futhi kancane kancane.

(2) Ukuphuka kwepayipi lensimbi le-groove

1. Hlelisa izimbambo zokushisela ezingaphakathi zodonga lwengxenye yomlomo wepayipi ukuze unciphise ukumelana komsele.

2, Lungisa i-axis yepayipi lensimbi kanye nemishini yokugenca, edinga ipayipi lensimbi kanye nemishini yokugoqa ukuze kube izinga.

3. Lungisa isivinini sokucindezela, isivinini sokucindezela asikwazi ukweqa okubekiwe, sebenzisa amandla ngokulinganayo futhi kancane.

4. Hlola ububanzi nemodeli yerola esekelayo kanye ne-pressure roller ye-rolling groove, futhi uhlole ukuthi akukho yini ukungafani kusayizi wamarola amabili, okungase kubangele ukubanjwa.

5. Sebenzisa i-vernier caliper ukuze uhlole ukuthi i-groove yepayipi yensimbi icacisiwe.

(3) I-groove eyakhiwe umshini we-groove rolling kufanele ihlangabezane nezimfuneko ezilandelayo

I-1, Indawo yokuphela kwepayipi engxenyeni ye-groove kufanele ibe bushelelezi futhi ingabi nokungalingani kanye nama-roll marks.

2, Isikhungo se-groove kufanele sigxile ngodonga lwamapayipi, ububanzi nokujula kwe-groove kufanele kuhlangabezane nezidingo, futhi uhlole ukuthi uhlobo lwengxenye ye-clamp lulungile.

3. Gcoba okokuthambisa iringi yokuvala irabha bese uhlola ukuthi iringi yokuvala irabha yonakele yini. I-lubricant akumele ibe yinto yokuthambisa kawoyela.

Uxhumano olushiselwe

1. Umlomo wepayipi wepayipi yensimbi yama-galvanized awukho emgqeni oqondile futhi kunenkinga yomlomo we-oblique wepayipi yensimbi ngemva kokubhoboza. Kunconywa ukusika ikhanda lepayipi isikhathi esifushane ngaphambi kokucubungula.

I-2, Ngemva kokuba imibhobho yamapayipi ensimbi enezinsimbi ixhunyiwe, ama-nozzles amabili awaxhunyiwe ngokuqinile, okuholela ekugqileni okungalingani kokuhlangene okuhlanganisiwe; futhi ipayipi i-elliptical ngenxa yezizathu zayo noma ama-bumps ezokuthutha. Kunconywa ukusika ikhanda lepayipi isikhathi esifushane. Lungisa futhi.

3. Ngemva kokuba imibhobho yamapayipi ensimbi ebilisiwe, kuvela amabhamuza emibhobolweni:

4. Ngenxa yezizathu zobuchwepheshe ngesikhathi sokushisela.

5. Kunamaqhuqhuva e-zinc ku-nozzle, angabangela ubunzima bokushisela namabhamuza. Uma amaqhuqhuva e-zinc emakhulu kakhulu futhi amapayipi amaningi kakhulu, izigaxana ezilula ze-zinc kufanele zisuswe.

Uxhumano lwezintambo

1, Ibhande elinentambo: Ihupho yepayipi kanye nebhande elinentambo akukwazi ukuthintwa ngokuphelele, kuxegiswe, kunqamule ingxenye yebhakede engahleliwe, bese uphinda ufake intambo.

2. Intambo yepayipi yensimbi kanye nentambo ye-hoop yepayipi ayifani futhi ayikwazi ukuxhunywa. Ihupho yepayipi kufanele ishintshwe noma okokusebenza kufanele kulungiswe futhi kucushwe kabusha.

3. Ukuphrinta okungekho ngemva kokucutshungulwa kwepayipi lensimbi: Linganisa ukuthi ubukhulu bodonga lwepayipi lensimbi bungahlangabezana yini nezidingo zokujiya ezijwayelekile zepayipi elinentambo

| Uhlobo | Ipayipi yensimbi ye-EN10210 |

| Ibanga | S235jrh(1.0039), s275j0h(1.0149), s275j2h(1.0138), s355j0h(1.0547), s355j2h(1.0576), s355k2h(1.0512), 1. 5.9(1.0512), 7(9), 7(9), 5.9(1.0512), s27(1.0512), s27(1.0149), s275j2h(1.0138), s355j0h(1.0547) s(5,5,5) s420nh(1.8750), s420nlh(1.8751), s460nh(1.8953), s460nlh(1.8956), s235jrh(1.0039), s275j(1.8750), s5(1039), s420n s460nh(1.8953), s235jrh(1.0039), s275j5(j5h), 5j5(04j), 5h(1.8751), 5h(1.8751), s460nh(1.8953) 1.0551, 2 s355j2h(1.0552)(1.0493), s275nlh(1.0497), s355nh(1.0539), s355nlh(1.0549), s420nh(1.8750), s420nl5nh6), 1.4 s460nlh(1.8956), s275mh(1.8453)(m843)s275ml (s355mlh(1.8846)s420mh(1.8847)s420mlh(1.8848)s460mh(1.8849)s460mlh(1.8850) |

| Ubukhulu | 3 mm - 30 mm |

| Isitifiketi | Ul api |

| Isevisi yokucubungula | Ukugoba, ukushisela, ukuqaqa, ukubhoboza, ukusika |

| Igama lomkhiqizo | Ipayipi lensimbi elingenamthungo |

| Isimo | Isikwele esiyindilinga. Unxande |

| Ubude | 3-12m |

| I-Moq | 1 ton |

| Ubuchwepheshe | Amakhaza ajingiwe ashisayo |