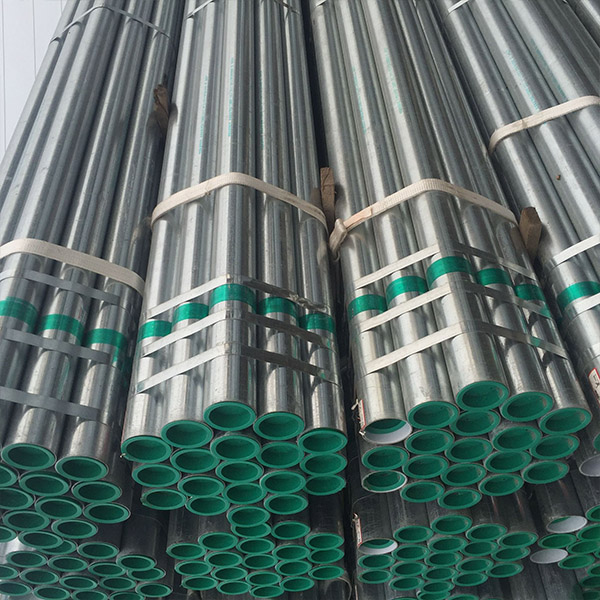

Ipayipi Elivunyiwe

Ukugeleza kwenqubo yilokhu:ishubhu elimnyama ukuwasha-amanzi ukuwasha-ukukha-amanzi okugeza-ukucwiliswa-aid-omisa-ashisayo dip galvanizing-ukufuthela kwangaphandle-ukufuthela kwangaphakathi-umoya ukupholisa-amanzi ukupholisa -Pasivation-amanzi ukugeza-ukuhlola-isisindo-isitoreji.

1, Brand kanye nokwakheka kwamakhemikhali

Ibanga kanye nokwakheka kwamakhemikhali ensimbi yamapayipi ensimbi kufanele kuhambisane nebanga kanye nokwakheka kwamakhemikhali ensimbi yamapayipi amnyama njengoba kucaciswe ku-GB/T3091.

2, Indlela yokukhiqiza

Indlela yokukhiqiza yepayipi elimnyama (i-welding yesithando somlilo noma i-welding kagesi) ikhethwa ngumkhiqizi. I-hot-dip galvanizing isetshenziselwa ukuvuthela.

3. Intambo nepayipi ehlangene

(a) Emapayipini ensimbi anezinsimbi ezilethwa ngemicu, izintambo kufanele zenziwe ngomshini ngemva kokufaka uthayela. Uchungechunge kufanele luhambisane nemithetho ye-YB 822.

(b) Izihlanganisi zamapayipi ensimbi kufanele zihambisane ne-YB 238; amalunga epayipi lensimbi elithambile elithambile kufanele ahambisane ne-YB 230.

4. Izakhiwo zikamshini Izakhiwo zokuwumshini zamapayipi ensimbi ngaphambi kokuvuthwa kufanele zihlangabezane nezidingo ze-GB 3091.

5. Ukufana kongqimba oluthathiwe Ipayipi lensimbi elakhiwe kufanele lihlolwe ukufana kongqimba oluvunyiwe. Isampula yepayipi yensimbi akufanele iphenduke ibe bomvu (i-copper-plated) ngemva kokucwiliswa kwisisombululo se-copper sulfate izikhathi ezi-5 ezilandelanayo.

6, Cold bend test ipayipi lashukumisa steel nge ububanzi okuzisholo hhayi ngaphezu 50mm kufanele kube abandayo bend test. I-engeli yokugoba ingu-90°, futhi i-radius egobayo iphinda izikhathi ezingu-8 ububanzi bangaphandle. Akukho ukugcwalisa ngesikhathi sokuhlolwa, futhi i-weld yesampula kufanele ibekwe ngaphandle noma engxenyeni engenhla yesiqondiso sokugoba. Ngemuva kokuhlolwa, akufanele kube nokuqhekeka nokuxebuka kwesendlalelo se-zinc kusampula.

I-7, Ukuhlolwa kwengcindezi yamanzi Ukuhlolwa kwengcindezi yamanzi kufanele kwenziwe ku-clarinet, futhi ukuhlolwa kwamanje kwe-eddy kungasetshenziswa esikhundleni sokuhlolwa kwengcindezi yamanzi. Ingcindezi yokuhlola noma usayizi wesampula yokuqhathanisa yokuhlolwa kwamanje kwe-eddy izohlangabezana nezidingo ze-GB 3092. Izici zokushintshwa kwensimbi ziyizinkomba ezibalulekile zokuqinisekisa ukusebenza kokugcina kokusetshenziswa (izakhiwo zemishini) yensimbi.

① Amandla e-Tensile (σb):Amandla amakhulu (Fb) isampula eliwathwalayo lapho ephuka phakathi nenqubo yokwelula, ahlukaniswe ingcindezi (σ) etholwe ngokuhlukanisa indawo yasekuqaleni ye-cross-sectional (So) yesampula, abizwa ngokuthi amandla e-Resistance Tensile (σb) , iyunithi ithi N/mm2 (MPa). Imele ikhono eliphezulu lensimbi yokumelana nokulimala ngaphansi kwamandla aqinile. Kufomula: Fb-amandla aphezulu isampula eliwathwalayo lapho liphulwa, N (Newton); I-So-indawo yokuqala ye-cross-sectional yesampula, mm2.

②Iphoyinti lokukhiqiza (σs):Okokusebenza kwensimbi okunomphumela wokukhiqiza, ingcindezi lapho isampula ingaqhubeka nokukhula ngaphandle kokukhulisa amandla phakathi nenqubo yokwelula ibizwa ngokuthi iphoyinti lokukhiqiza. Uma amandla ehla, amaphuzu okukhiqiza aphezulu naphansi kufanele ahlukaniswe. Iyunithi yephoyinti lesivuno ngu-N/mm2 (MPa). Iphuzu Lokuvuthela Elingaphezulu (σsu): Ukucindezeleka okukhulu ngaphambi kokuba isifanekiso siveze futhi amandla ehla okokuqala; Iphoyinti Lesivuno Esiphansi (σsl): Ingcindezi encane esigabeni sokukhiqiza lapho umphumela wesikhashana wokuqala unganakwa. Kuphi: Fs--isivuno samandla (okuqhubekayo) phakathi nenqubo yokuqina yesampula, N (Newton) Ngakho--indawo yokuqala yesiqephu sesampula, mm2.

③ Ukukhula ngemva kokuphuka:(σ) Esivivinyweni sokuqina, iphesenti lobude begeji likhuphuke ngemva kokuba isampuli yephulwe ukuya kubude begeji yangempela ibizwa ngokuthi ukwelulwa. Kuvezwe ngo-σ, iyunithi ithi %. Kufomula: L1-ubude begeji yesampula ngemva kokuphuka, ngo-mm; L0-ubude begeji yoqobo yesifanekiso, ngo-mm.

④ Ukuncishiswa kwendawo:(ψ) Ekuhlolweni kwe-tensile, iphesenti lokuncishiswa okuphezulu kwendawo ye-cross-sectional kububanzi obuncishisiwe besampula ngemva kokuba isampula yephulwe endaweni yokuqala ye-cross-sectional ibizwa ngokuthi ukuncishiswa kwendawo. Kuvezwe ngo-ψ, iyunithi ithi %. Kufomula: I-S0-indawo yokuqala yesiqephu sesampula, mm2; I-S1-indawo encane ehlukanisayo kububanzi obuncishisiwe besampula ngemva kokwephulwa, mm2.

⑤ Inkomba yokuqina:Ikhono lezinto zensimbi ukumelana nokungeniswa kwezinto eziqinile ebusweni kubizwa ngokuthi ubulukhuni. Ngokwezindlela ezihlukene zokuhlola kanye nobubanzi bokusebenza, ubulukhuni bungahlukaniswa ngokuqina kwe-Brinell, ukuqina kwe-Rockwell, ukuqina kwe-Vickers, ukuqina koShore, ubulukhuni obuncane kanye nobulukhuni bezinga lokushisa eliphezulu. Kunamapayipi amathathu asetshenziswa kakhulu: Brinell, Rockwell, Vickers hardness.

Ukuqina kwe-Brinell (HB):Sebenzisa ibhola lensimbi noma ibhola le-carbide elinobubanzi obuthile ukuze ulicindezele ebusweni besampula ngamandla okuhlola ashiwo (F), khipha amandla okuhlola ngemva kwesikhathi esibekiwe sokubamba, futhi ulinganise ububanzi bokuhlehlisa ebusweni isampula (L). Inani lobulukhuni be-Brinell yi-quotient etholwe ngokuhlukanisa amandla okuhlola ngendawo eyindilinga yendawo yokuhlehlisa. Ivezwe nge-HBS (ibhola lensimbi), iyunithi ithi N/mm2 (MPa).