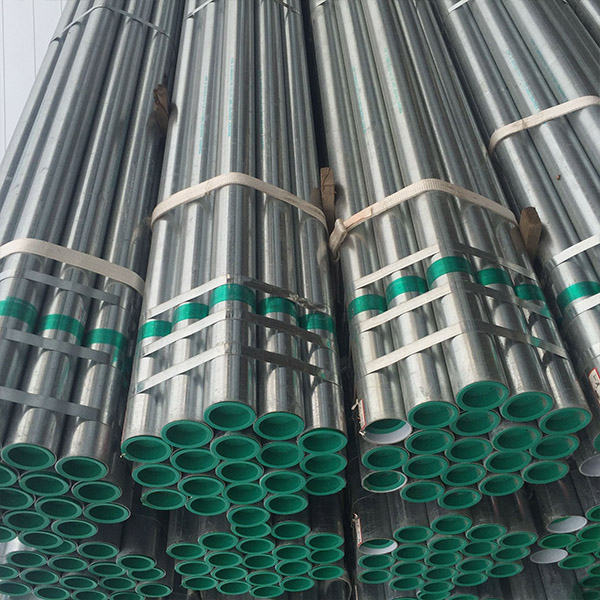

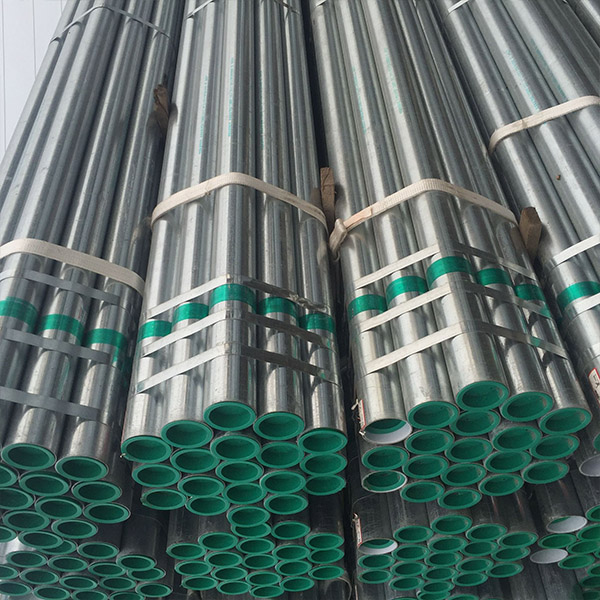

Ipayipi Elinothayela Elishisayo

Ipayipi elinothayela elishisayo

Ipayipi elinothayela elidiphu elishisayo elokwenza insimbi encibilikisiwe isabelane ne-iron matrix ukuze ikhiqize ungqimba lwengxubevange, ukuze i-matrix ne-coating kuhlanganiswe. I-hot-dip galvanizing iwukuba kuqala uvuse ipayipi lensimbi. Ukuze kukhishwe i-iron oxide ebusweni bepayipi lensimbi, ngemva kokukhetha, ihlanzwa ethangini nge-ammonium chloride noma i-zinc chloride isixazululo samanzi noma isixazululo esinamanzi esixubile se-ammonium chloride ne-zinc chloride, bese sithunyelwa ithangi lokucwilisa elishisayo. I-hot-dip galvanizing inezinzuzo zokugqoka okufanayo, ukunamathela okuqinile nokuphila isikhathi eside. I-matrix yepayipi lensimbi elinothayela elishisayo idiphu ibhekana nokusabela okuyinkimbinkimbi ngokomzimba namakhemikhali ngesisombululo sokucwenga esincibilikisiwe ukuze kwakhe ungqimba lwengxube ye-zinc-iron engagqwali enesakhiwo esihlangene. Ungqimba lwe-alloy luhlanganiswe nongqimba oluhlanzekile lwezinc kanye ne-matrix yepayipi lensimbi, ngakho ukumelana nokugqwala kunamandla.

Ipayipi elibandayo elinothayela

Ipayipi elibandayo elinothayela liyi-electro-galvanized, futhi inani lokufaka uthayela lincane kakhulu, lingama-10-50g/m2 kuphela, futhi ukumelana kwalo nokugqwala kuhluke kakhulu kunalelo lepayipi elifakwe emanzini ashisayo. Abakhiqizi bamapayipi bamapayipi abahlelekile, ukuze kuqinisekiswe ikhwalithi, iningi labo alisebenzisi i-electro-galvanized (i-plating ebandayo). Yilawo mabhizinisi amancane kuphela anemishini emincane nephelelwe yisikhathi asebenzisa i-electro-galvanization, futhi vele amanani awo ashibhe uma kuqhathaniswa. UMnyango Wezokwakha usumemezele ngokusemthethweni ukuthi kufanele kuqedwe amapayipi anothayela abandayo anobuchwepheshe obuphelelwe yisikhathi, namapayipi anothayela abandayo awavunyelwe ukuthi asetshenziswe njengamapayipi amanzi negesi. Isendlalelo esivundisiwe sepayipi lensimbi elibandayo liyisingqimba se-electroplated, futhi ungqimba lwezinc luhlukaniswa ne-substrate yepayipi lensimbi. Ungqimba lwezinc luncane, futhi ungqimba lwezinc lumane lunamathele esisekelweni sepayipi lensimbi futhi liwe kalula. Ngakho-ke, ukumelana nokugqwala kwayo kubi. Ezindlini ezisanda kwakhiwa, akuvunyelwe ukusebenzisa amapayipi ensimbi abandayo njengamapayipi okuhambisa amanzi.

Ukujiya kodonga okuzisholo (mm): 2.0, 2.5, 2.8, 3.2, 3.5, 3.8, 4.0, 4.5.

Amapharamitha we-coefficient (c): 1.064, 1.051, 1.045, 1.040, 1.036, 1.034, 1.032, 1.028.

Qaphela: Izakhiwo zemishini yensimbi iyinkomba ebalulekile yokuqinisekisa ukusebenza kokugcina kokusetshenziswa (izakhiwo zemishini) yensimbi, futhi kuncike ekubunjweni kwamakhemikhali ensimbi kanye nesistimu yokwelapha ukushisa. Esilinganisweni sepayipi lensimbi, ngokwezidingo ezihlukene zohlelo lokusebenza, izakhiwo eziqinile (amandla okuqina, amandla okukhiqiza noma iphuzu lesivuno, ukuphakama), izinkomba zokuqina nokuqina zicacisiwe, kanye nezakhiwo zokushisa eziphakeme neziphansi ezidingwa abasebenzisi.

Amabanga ensimbi: Q215A; Q215B; Q235A; Q235B.

I-Test pressure value/Mpa: D10.2-168.3mm ingu-3Mpa; I-D177.8-323.9mm ingu-5Mpa

Izinga likazwelonke lamanje

Amazinga kazwelonke kanye namazinga osayizi wamapayipi anamathani

I-GB/T3091-2015 Ipayipi lensimbi elishiselwe ukuthutha uketshezi olunengcindezi ephansi

GB/T13793-2016 Longitudinal kagesi ashiselwe ipayipi yensimbi

I-GB/T21835-2008 usayizi wepayipi lensimbi elishiselwe kanye nesisindo sobude beyunithi