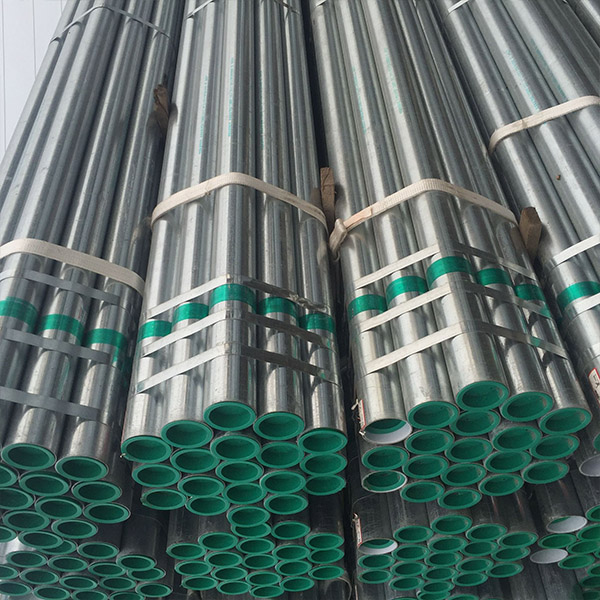

I-Hot Dip Galvanized Steel

Ukujiya kodonga okuzisholo (mm): 2.0, 2.5, 2.8, 3.2, 3.5, 3.8, 4.0, 4.5.

Amapharamitha we-coefficient (c): 1.064, 1.051, 1.045, 1.040, 1.036, 1.034, 1.032, 1.028.

Qaphela: Izakhiwo zemishini yensimbi iyinkomba ebalulekile yokuqinisekisa ukusebenza kokugcina kokusetshenziswa (izakhiwo zemishini) yensimbi, futhi kuncike ekubunjweni kwamakhemikhali ensimbi kanye nesistimu yokwelapha ukushisa. Esilinganisweni sepayipi lensimbi, ngokwezidingo ezihlukene zohlelo lokusebenza, izakhiwo eziqinile (amandla aqinile, amandla okukhiqiza noma iphuzu lesivuno, ukuphakama),izinkomba zokuqina nokuqina zicacisiwe, kanye nezakhiwo zokushisa eziphakeme neziphansi ezidingwa abasebenzisi.

Amabanga ensimbi: Q215A; Q215B; Q235A; Q235B.

I-Test pressure value/Mpa: D10.2-168.3mm ingu-3Mpa; I-D177.8-323.9mm ingu-5Mpa

Amazinga kazwelonke kanye namazinga osayizi wamapayipi anamathani

I-GB/T3091-2015 Ipayipi lensimbi elishiselwe ukuthutha uketshezi olunengcindezi ephansi

GB/T13793-2016 Longitudinal kagesi ashiselwe ipayipi yensimbi

I-GB/T21835-2008 usayizi wepayipi lensimbi elishiselwe kanye nesisindo sobude beyunithi

Ukugeleza kwenqubo yilokhu:ishubhu elimnyama ukuwasha-amanzi ukuwasha-ukukha-amanzi okugeza-ukucwiliswa-aid-omisa-ashisayo dip galvanizing-ukufuthela kwangaphandle-ukufuthela kwangaphakathi-umoya ukupholisa-amanzi ukupholisa -Pasivation-amanzi ukugeza-ukuhlola-isisindo-isitoreji.

Amapayipi okuvamise ukuthiwa ngawo galvanized, amapayipi ayisithako asetshenziselwa igesi, kanti uhlobo lwamapayipi ensimbi asetshenziselwa ukufudumeza nawo angamapayipi. Amapayipi anamathangi asetshenziswa njengamapayipi amanzi. Ngemva kweminyaka eminingana yokusetshenziswa, ukugqwala nokungcola okuningi kukhiqizwa emapayipini, futhi amanzi aphuzi aphumayo awagcini nje ngokungcolisa i-sanitary ware, Futhi ahlanganiswe nama-bacteria azalela odongeni lwangaphakathi olungalingani, futhi ukugqwala kubangela okuqukethwe okuphezulu kwezinsimbi ezisindayo emanzini, okufaka engozini kakhulu impilo yomzimba womuntu.

Indlela yokuxhuma ipayipi lensimbi: intambo, ishiselwe.

Ukuxhumana kwe-groove

(1) Ukuqhekeka kwe-roll groove weld

1. Hlelisa izimbambo zokushisela odongeni lwangaphakathi lwengxenye ye-pressure groove yenozzle ukuze unciphise ukumelana komsele.

2, Lungisa i-axis yepayipi lensimbi kanye nemishini yokugenca, futhi udinga ipayipi lensimbi kanye nemishini yokugenca ukuze kube izinga.

3. Lungisa isivinini sokucindezela i-groove, futhi isikhathi sokwenza i-groove asikwazi ukudlula umgomo, sebenzisa amandla ngokulinganayo futhi kancane kancane.

(2) Ukuphuka kwepayipi lensimbi le-groove

1. Hlelisa izimbambo zokushisela ezingaphakathi zodonga lwengxenye yomlomo wepayipi ukuze unciphise ukumelana komsele.

2, Lungisa i-axis yepayipi lensimbi kanye nemishini yokugenca, edinga ipayipi lensimbi kanye nemishini yokugoqa ukuze kube izinga.

3. Lungisa isivinini sokucindezela, isivinini sokucindezela asikwazi ukweqa okubekiwe, sebenzisa amandla ngokulinganayo futhi kancane.

4. Hlola ububanzi nemodeli yerola esekelayo kanye ne-pressure roller ye-rolling groove, futhi uhlole ukuthi akukho yini ukungafani kusayizi wamarola amabili, okungase kubangele ukubanjwa.

5. Sebenzisa i-vernier caliper ukuze uhlole ukuthi i-groove yepayipi yensimbi icacisiwe.

(3) I-groove eyakhiwe umshini we-groove rolling kufanele ihlangabezane nezimfuneko ezilandelayo

I-1, Indawo yokuphela kwepayipi engxenyeni ye-groove kufanele ibe bushelelezi futhi ingabi nokungalingani kanye nama-roll marks.

2, Isikhungo se-groove kufanele sigxile ngodonga lwamapayipi, ububanzi nokujula kwe-groove kufanele kuhlangabezane nezidingo, futhi uhlole ukuthi uhlobo lwengxenye ye-clamp lulungile.

3. Gcoba okokuthambisa iringi yokuvala irabha bese uhlola ukuthi iringi yokuvala irabha yonakele yini. I-lubricant akumele ibe yinto yokuthambisa kawoyela.

Uxhumano olushiselwe

1. Umlomo wepayipi wepayipi yensimbi yama-galvanized awukho emgqeni oqondile futhi kunenkinga yomlomo we-oblique wepayipi yensimbi ngemva kokubhoboza. Kunconywa ukusika ikhanda lepayipi isikhathi esifushane ngaphambi kokucubungula.

I-2, Ngemva kokuba imibhobho yamapayipi ensimbi enezinsimbi ixhunyiwe, ama-nozzles amabili awaxhunyiwe ngokuqinile, okuholela ekugqileni okungalingani kokuhlangene okuhlanganisiwe; futhi ipayipi i-elliptical ngenxa yezizathu zayo noma ama-bumps ezokuthutha. Kunconywa ukusika ikhanda lepayipi isikhathi esifushane. Lungisa futhi.

3. Ngemva kokuba imibhobho yamapayipi ensimbi ebilisiwe, kuvela amabhamuza emibhobolweni:

4. Ngenxa yezizathu zobuchwepheshe ngesikhathi sokushisela.

5. Kunamaqhuqhuva e-zinc ku-nozzle, angabangela ubunzima bokushisela namabhamuza. Uma amaqhuqhuva e-zinc emakhulu kakhulu futhi amapayipi amaningi kakhulu, izigaxana ezilula ze-zinc kufanele zisuswe.

Uxhumano lwezintambo

1, Ibhande elinentambo: Ihupho yepayipi kanye nebhande elinentambo akukwazi ukuthintwa ngokuphelele, kuxegiswe, kunqamule ingxenye yebhakede engahleliwe, bese uphinda ufake intambo.

2. Intambo yepayipi yensimbi kanye nentambo ye-hoop yepayipi ayifani futhi ayikwazi ukuxhunywa. Ihupho yepayipi kufanele ishintshwe noma okokusebenza kufanele kulungiswe futhi kucushwe kabusha.

3. Ukuphrinta okungekho ngemva kokucutshungulwa kwepayipi lensimbi: Linganisa ukuthi ubukhulu bodonga lwepayipi lensimbi bungahlangabezana yini nezidingo zokujiya ezijwayelekile zepayipi elinentambo