I-Laser Tailor-Welded Boiler Plate

Ezokuthutha: Sekela ezokuthutha zasolwandle

Amazinga: AiSi, ASTM, JIS

Ibanga: Ar360 400 450 NM400 450 500

Indawo Yomsuka: Shandong, China

Imodeli: Ar360 400 450 NM400 450 500

Uhlobo: ipuleti lensimbi, ipuleti lensimbi

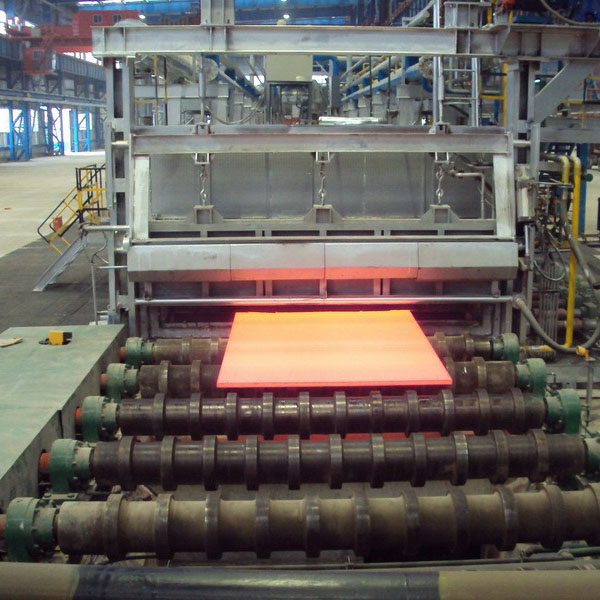

Inqubo: I-Hot rolled

Ukwelashwa okungaphezulu: ukugqoka

Isicelo: i-boiler plate

Ububanzi: 2000mm noma njengoba kudingeka

Ubude: 5800mm 6000mm 8000mm

Ukubekezelela: ±5%

Izinkonzo zokucubungula: ukugoba, ukushisela, ukuqaqa, ukusika, ukubhoboza

Igama lomkhiqizo: Ipuleti lensimbi elingagqoki

Impahla: NM450 500 550 640 NM4400 450 500

Ubukhulu: 3mm-100mm noma njengoba kudingeka

Ukupakisha: Iphakheji elijwayelekile elivumela umoya

Ukusetshenziswa: Imboni

Umumo: unxande

Ikhono Lokuhlinzeka: 2000 tons/ton ngenyanga

Imininingwane yokupakisha: ukupakisha okuseqophelweni eliphezulu komoya, futhi ngokuya ngezidingo zamakhasimende.

Ichweba: Qingdao, Tianjin, Shanghai

Ukuthuthukiswa kwe-20g eJinan Iron ne-Steel Group Corporation (okufingqiwe ngokuthi i-Jigang) kwenziwa eminyakeni engaphezu kweshumi edlule, kodwa kunqunyelwe ezingeni lemishini yenqubo nemishini ngaleso sikhathi, ukusebenza kwepuleti lensimbi kwakungazinzile, futhi kwakukhona. ngokuvamile izinkinga zokugoba okubandayo okungahambisani nokuguga. Izinyathelo ezilandelayo zizothathwa ukuze kuthuthukiswe izindawo ezibandayo zokugoba nokuguga kanye nokuqinisekisa ukuqina komthelela wezinga lokushisa eliphansi:

(1) Lungisa izingxenye zokulawula zangaphakathi futhi wandise umkhawulo ophansi wokuqukethwe kwe-manganese ube ngu-0.65%.

(2) Umsebenzi wokucwenga "kaZiqu-zintathu" wokuphakela ngocingo, ukulawulwa kwezinga lokushisa nokuvunguza kwe-argon kwamukelwa.

(3) Lawula ngokuqinile izinga lokushisa elithelayo.

(4) Okuqukethwe kwe-microalloyed element Ti kukhuphuke kusuka ku-0.003% kuya ngaphezu kuka-0.008%. (5) Yonke inqubo yokuthulula yokuvikela yamukelwa ukunciphisa ukumuncwa kwe-n

Umzila wenqubo yokukhiqiza:I-20g (Ti) i-boiler plate iwuhlobo lwensimbi olunezidingo eziphezulu zezakhiwo zemishini ezibanzi, insimbi emsulwa uma kuqhathaniswa, kanye nokwakheka kwezingxenye ezincibilikayo nezinto ezincane ze-microalloying ezizwela kakhulu emiphumeleni yezakhiwo ezahlukahlukene. Ngakho-ke, isihluthulelo senqubo yokukhiqiza engu-20g (Ti) ukuthuthukisa ukwakheka kokuncibilika, ukunciphisa inani eliphelele lokufakwa ensimbi, khetha izakhi ezifanele ze-microalloying, ukusebenzisa ukugoqa okulawulwayo, ukuthuthukisa ikhwalithi yepuleti, nokuzinzisa ukusetshenziswa umthelela wokuguga. Umzila wezobuchwepheshe wama-20g uthi: insimbi encibilikisiwe yekhwalithi ephezulu → ukwelashwa kokuhlanza → ukuncibilikiswa kokwenziwa ngcono kokwakheka kanye nokuhlanzwa kwensimbi → i-microalloying kanye nokucwengisiswa kwensimbi encibilikisiwe → ukusakazwa kokuvikela → i-slab yekhwalithi ephezulu → ukushisa okulawulwayo → ukugoqa okulawulwa izinga lokushisa → ukuma kwepuleti kanye ukulawula ukujiya →Lawula ukupholisa→umkhiqizo.

Ubuchwepheshe bebhodi lebhodi le-laser elithungayo elingenalutho neliqhubekayo eliguquguqukayo lesiphambano

1. I-Tailor Welded Blanks (i-Tailor Welded Blanks, i-TWB) isebenzisa i-laser njengomthombo wokushisa wokushisela ukuze ihlanganise futhi ishisele izinto ezihlukahlukene ezihlukahlukene, ugqinsi oluhlukene, nezindwangu ezihlukene zensimbi, insimbi engagqwali, ingxubevange ye-aluminium, njll. ibe yipuleti lonke.

2. Ngokusebenzisa ubuchwepheshe bokushisela obulungiselelwe nge-laser, kungenzeka ukuhlanganisa ngokunengqondo izinto zobukhulu obuhlukahlukene obuhlukahlukene kanye namazinga wamandla ngokuya ngezimo zokucindezeleka zezingxenye zesakhiwo, uthuthukise ukuqina kwesakhiwo ngenkathi unciphisa isisindo sezingxenye, futhi wandise izinga lokusebenzisa. wezinto zokwakha futhi unciphise inani lezingxenye. Inombolo yezingxenye ku-yenza inqubo ibe lula. Ubuchwepheshe bokushisela owenziwe nge-laser buye baba yindlela yobuchwepheshe eyinhloko yemoto engasindi, futhi isetshenziswe kumamodeli abakhiqizi abaningi. Ikakhulukazi esetshenziswa ngaphambili nangemuva amaphaneli angaphakathi komnyango, imishayo yobude bangaphambili nangemuva, amaphaneli aseceleni, amaphaneli aphansi, izinsika A, B, no-C ngaphakathi komnyango, amakhava amasondo namaphaneli angaphakathi esiqu, njll.

3. I-Tailor Rolling Blanks (TRB), ebizwa nangokuthi amapuleti okuqina okuhlukile, ibhekisela ekushintsheni kwesikhathi sangempela kosayizi wegebe le-roll ngekhompyutha phakathi nenqubo yokugingqika yepuleti lensimbi, ukuze ipuleti eligoqiwe elizacile libe nokunqunywa kusengaphambili. isiqondiso eduze nesiqondiso sokugoqa. Umumo wesiphambano esiguquguqukayo ngokwezifiso.

4. Ubuchwepheshe obuqhubekayo bephaneli yesiphambano esiguquguqukayo busetshenziswe kabanzi ekwenzeni izingxenye zesakhiwo somzimba, njengesembozo senjini, insika engu-B, i-chassis yomzimba, umhlahlandlela we-motor spacer, iphaneli yangaphakathi yekholomu ephakathi, i-mudguard nebhokisi lokuphahlazeka, njll., futhi isetshenziswe ngempumelelo kwa-Audi, BMW, Volkswagen, GM nezinye izinhlobo.

5. I-laser yokushisela i-laser kanye nobuchwepheshe obuguquguqukayo obuguquguqukayo obuqhubekayo bushintsha ukushuba kwezinto zokugxiviza ngezindlela ezahlukene zobuchwepheshe, futhi zisetshenziselwa ukuxazulula inkinga yezidingo ezahlukene zomthwalo othwala imithwalo yezingxenye ezahlukene zezingxenye zezimoto ezingaphansi komthwalo. Uma kuqhathaniswa nalokhu okubili, inzuzo yobuchwepheshe be-laser welding eyenziwe ngomsiki isekuguquguqukeni kwayo, okukwazi ukubona ukuhlanganisa kwanoma yisiphi isikhundla kanye nokuhlanganisa izinto ezahlukene. Inzuzo yobuchwepheshe obuguquguqukayo obuqhubekayo be-cross-section ukuthi awukho umthungo wokushisela, ukushintshwa kokuqina eduze kwesiqondiso sobude kuthambile, kunokwakheka okungcono, nekhwalithi yangaphezulu yinhle, ukusebenza kahle kokukhiqiza kuphezulu, futhi izindleko phansi. Imithwalo, imishini yezokwelapha, igobolondo lesithuthuthu; imoto, uphahla lwangaphakathi lwebhasi, ideshibhodi; ukusekelwa kwesihlalo, iphaneli yomnyango, ifreyimu yefasitela, njll.

| I-A516 Gr.60 | I-A516 Gr.65 | I-A516 Gr.70 | |

| Amandla Aqinile(Ksi) | 60-80 | 65-85 | 70-90 |

| Amandla Okuqina (Mpa) | 415-550 | 450-585 | 485-620 |

| Amandla Okukhiqiza (Ksi) | 32 | 35 | 38 |

| Isivuno Amandla (Mpa) | 220 | 240 | 260 |

| 200mm Ubude(%) | 21 | 19 | 17 |

| 50mm Ubude (%) | 25 | 23 | 21 |

| Ubukhulu obukhulu (Mm) | 205 | 205 | 205 |