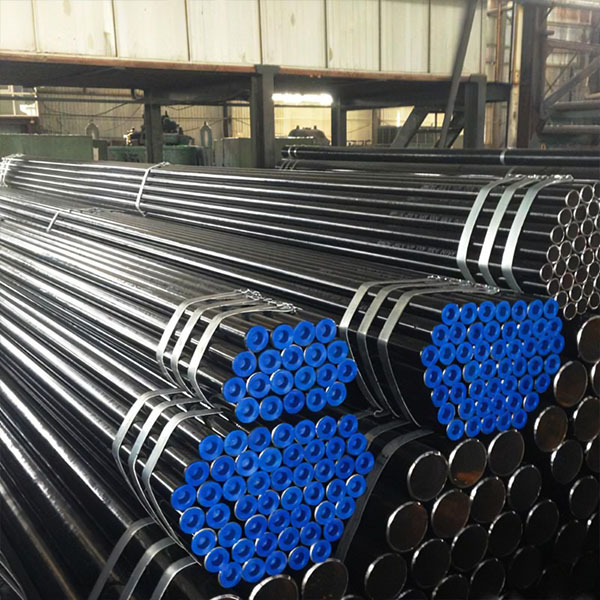

I-P91 Solid Alloy Tube

P91 ingxubevange ipayipi ngokusho GB/T8162-87

4.1. Imininingwane: Ububanzi bangaphandle beshubhu eligoqelwe ngokushisayo ngu-32 ~ 630mm. Ubukhulu bodonga buyi-2.5 ~ 75mm. Ububanzi obungaphandle bepayipi eligoqiwe (elibandayo elidonswe) lingu-5∽200mm. Ubukhulu bodonga buyi-2.5-12mm.

4.2. Ikhwalithi yokubukeka: indawo yangaphakathi nangaphandle yepayipi lensimbi akumele ibe nemifantu, ukugoqa, ama-roll, i-delamination, imigqa yezinwele kanye nezibazi. Lezi ziphambeko kufanele zisuswe ngokuphelele, futhi ubukhulu bodonga nobubanzi bangaphandle akumele budlule ukuchezuka okungalungile ngemva kokususwa.

Indlela yokukhiqiza

Ngokwezindlela ezahlukene zokukhiqiza, ingahlukaniswa ngamashubhu ashisayo, amashubhu abandayo, amashubhu adonswa abandayo, amashubhu akhishwe, njll.

1.1. Amashubhu engxubevange e-P91 agingqiwe ashisayo ngokuvamile akhiqizwa ezigayweni zokugingqa ezizenzakalelayo. Ithubhu eliqinile liyahlolwa futhi lihlanzwe amaphutha angaphezulu, lisikwe ubude obudingekayo, ligxile ekugcineni kwepayipi elinezimbobo, bese lithunyelwa esithandweni sokushisa ukuze lishiswe futhi ligwazwe emshinini wokubhoboza. Lapho imbobo ijikeleza ngokuqhubekayo futhi ithuthuka ngesikhathi esifanayo, ngaphansi kwesenzo se-roller nepulaki, kancane kancane kwakheka umgodi ngaphakathi kweshubhu elingenalutho, elibizwa ngokuthi ishubhu le-capillary. Bese ithunyelwa kumshini wokugaya ozenzakalelayo ukuze uqhubeke nokuginqika. Ekugcineni, lonke ugqinsi lodonga lufaniswa umshini wokulinganisa, futhi ububanzi bulinganiswa ngomshini wokulinganisa ukuze kuhlangatshezwane nezidingo zokucaciswa. Kuyindlela ethuthuke kakhulu yokukhiqiza amapayipi engxubevange e-P91 agingqiwe ashisayo kusetshenziswa izigayo eziginqikayo zamapayipi.

1.2. Uma ufuna ukuthola amapayipi angenamthungo anosayizi omncane kanye nekhwalithi engcono, ukugoqa okubandayo, umdwebo obandayo, noma inhlanganisela yalezi zindlela ezimbili kufanele zisetshenziswe. Ukugoqa okubandayo kuvame ukwenziwa emshinini wokugingqa ophakeme kabili. Ipayipi lensimbi ligoqwe ngephasi elinyakaziswayo elakhiwe i-variable cross-section circular hole groove kanye nepulaki emile. Umdwebo obandayo uvame ukwenziwa emshinini wokudweba we-single-chain noma we-double-chain of 0.5 kuya ku-100T.

1.3. Indlela ye-extrusion ukubeka ishubhu elishisayo lingenalutho kusilinda esivaliwe se-extrusion, futhi induku enembobo kanye nenduku ye-extrusion ihamba ndawonye ukuze ikhiphe ingxenye ekhishwe emgodini omncane wokufa. Le ndlela ingakhiqiza amapayipi ensimbi anama-diameter amancane.

2.1. I-P91 alloy tube inezinhlobonhlobo zokusetshenziswa. Ipayipi lengxubevange lenjongo evamile le-P91 ligoqwa lisuka kunsimbi evamile ye-carbon structural, insimbi yesakhiwo esinengxubevange ephansi noma insimbi yesakhiwo sealloy, futhi inokukhipha okukhulu kakhulu. Isetshenziswa kakhulu njengamapayipi noma izingxenye zesakhiwo zokudlulisa uketshezi.

2.2. Ngokwezinjongo ezahlukene, ihlukaniswe yaba izinhlobo ezintathu zokuhlinzeka: a. Ngokusho kokwakheka kwamakhemikhali kanye nezakhiwo zemishini; b. Ngokusho kwezakhiwo zemishini; c. Ngokusho kokuhlolwa kwe-hydraulic. Amapayipi ensimbi ahlinzekwe ngokwezigaba u-a no-b, uma esetshenziselwa ukumelana nomfutho owuketshezi, nawo azohlolwa nge-hydraulic.

2.3. P91 ingxubevange amapayipi ngezinhloso ezikhethekile ahlanganisa P91 ingxubevange amapayipi for boilers, P91 ingxubevange amapayipi we geology kanye namapayipi nekhono for petroleum.

Izakhi eziyinhloko zamapayipi e-alloy yi-silicon, i-manganese, i-chromium, i-nickel, i-molybdenum, i-tungsten, i-vanadium, i-titanium, i-niobium, i-zirconium, i-cobalt, i-aluminium, ithusi, i-boron, umhlaba ongavamile, njll. inani elincane elidingekayo Ngaphezu kokugwema i-silicon, i-manganese, i-phosphorus, kanye isulfure, futhi iqukethe inani elithile lezakhi ze-alloying.Izakhi ze-alloying ensimbi zihlanganisa i-silicon, i-manganese, i-molybdenum, i-nickel, isulfure, i-vanadium, i-titanium, i-niobium, i-boron, i-lead, umhlaba ongavamile, njll. Uhlobo olulodwa noma ngaphezulu lwensimbi iyinsimbi. ebizwa ngokuthi i-alloy steels. Izinhlelo zensimbi ye-alloy ziyahlukahluka ngezimo zazo zensiza, izimo zokukhiqiza kanye nokusetshenziswa. Esikhathini esedlule, izinhlelo ze-nickel nezensimbi ziye zathuthukiswa emazweni angaphandle. I-China ithole ukuthi i-silicon, i-manganese, i-Vanadium, i-titanium, i-niobium, i-boron, i-lead, ne-rare earth alloy steel alloy steel system yenza cishe amaphesenti ayishumi engqikithi yokukhishwa kwensimbi. Ngokuvamile, amapayipi ensimbi ye-alloy angahlukaniswa abe yizinhlobo ezingu-8 ezinkulu ngokuvumelana nokusetshenziswa kwazo. Izinhlobo, yilezi: amapayipi ensimbi yesakhiwo sengxubevange, amapayipi ensimbi entwasahlobo, amapayipi ensimbi, insimbi yamapayipi ensimbi, ithuluzi lensimbi elinesivinini esikhulu, amapayipi ensimbi engagqwali, amapayipi ensimbi angangeni ekushiseni, amapayipi ensimbi kagesi ayi-silicon PC/ABS abe nokuhleleka okuhle futhi angacutshungulwa ezimotweni ezinkulu Izingxenye, njengezinsimbi zezimoto, zinokusebenza kwezindleko eziphezulu. Amapayipi ensimbi e-alloy enziwe ngensimbi evamile ye-carbon ngokungeza inani elifanele le-alloying element eyodwa noma ngaphezulu ekuhlukaniseni amapayipi ensimbi ye-iron-carbon alloy steel: amapayipi ensimbi ahlukaniswe amapayipi e-P91 alloy kanye namapayipi ensimbi yokushisela nokunye.