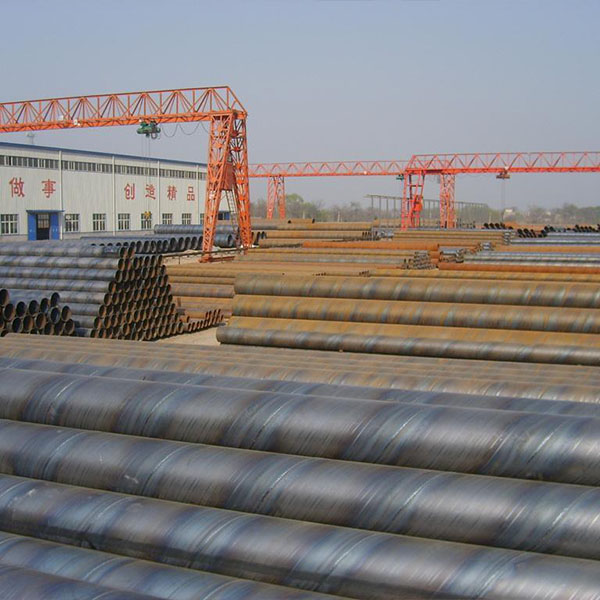

I-Q235B Spiral Tube

Amazinga asetshenziswa kakhulu amapayipi ensimbi okuvunguza ngokujwayelekile ahlukaniswe abe: SY/T5037-2000 (Indinganiso yoNgqongqoshe, ebizwa nangokuthi i-spiral seam submerged arc welded steel pipe yamapayipi ajwayelekile okuthutha uketshezi), GB/T9711.1-1997 (Izinga likaZwelonke, elibizwa nangokuthi ipayipi Ipayipi lensimbi elidlulisa uwoyela negesi Ingxenye yokuqala yezimo zokulethwa kobuchwepheshe: Ipayipi lensimbi leBanga A (GB/T9711.2 Ibanga Ipayipi lensimbi le-B liyadingeka ngokuqinile), i-API-5L (i-American Petroleum Institute, ebizwa nangokuthi ipayipi lensimbi yepayipi; ehlukaniswe ngamabanga amabili: i-PSL1 ne-PSL2), i-SY/T5040-92 (ipayipi lensimbi eli-Spiral elifakwe ngaphansi kwe-arc elishiselwe inqwaba).

(1) Izinto ezisetshenziswayo amakhoyili ensimbi ehlutshiwe, izintambo zokushisela, nama-fluxes. Ukuhlolwa okuqinile ngokomzimba namakhemikhali kuyadingeka ngaphambi kokutshala imali.

(2) Inhlanganisela yezinqe yekhanda nomsila wensimbi, kusetshenziswa i-arc yocingo olulodwa noma i-double-wire submered arc welding, ngemva kokuboshelwa epayipini lensimbi, ukushisela kwe-arc okuzenzakalelayo kusetshenziselwa ukulungisa ukushisela.

(3) Ngaphambi kokwakhiwa, i-strip yenziwa ileveli, ukunqunywa konqenqema, i-edge planing, ukuhlanzwa kwendawo kanye nokudlulisa, kanye nokwelashwa kwangaphambili kokugoba.

(4) Igeji yokulinganisa ingcindezi kagesi isetshenziselwa ukulawula ukucindezelwa kwamasilinda ezinhlangothini zombili zomhambisi ukuze kuqinisekiswe ukuhanjiswa okushelelayo komugqa.

(5) Yamukela isilawuli sangaphandle noma ukwakhiwa komqulu wokulawula wangaphakathi.

(6) Idivayisi yokulawula igebe lokushisela isetshenziselwa ukuqinisekisa ukuthi igebe lokushisela lihlangabezana nezidingo zokushisela, futhi ububanzi bepayipi, inani lokungalungi kahle kanye negebe lokushisela kulawulwa ngokuqinile.

(7) Kokubili ukushisela kwangaphakathi nokushisela kwangaphandle kusebenzisa umshini wokushisela we-American Lincoln kagesi wocingo olulodwa noma i-double-wire submerged arc welding, ukuze kutholwe ukucaciswa kokushisela okuzinzile.

(8) Ama-welds ahlolwa ithuluzi elisebenza ku-inthanethi le-ultrasonic automatic flaw, eliqinisekisa u-100% wokuhlolwa okungabhubhisi ama-spiral weld.

(9) Sebenzisa umshini wokusika i-plasma yomoya ukuze usike ipayipi lensimbi libe yizicucu ngazinye.

(10) Ngemva kokusika emapayipini ensimbi eyodwa, amapayipi ensimbi amathathu okuqala eqoqo ngalinye kufanele ahlolwe kuqala ukuze kuqinisekiswe ukuthi inqubo yokwenza amapayipi ifanelekile ngaphambi kokufakwa ngokusemthethweni ekukhiqizeni.

(11) Izingxenye ezinamamaki okuthola amaphutha e-sonic okuqhubekayo kumashisela zihlolwa nge-ultrasonic manual kanye ne-X-ray kabusha.

(12) Amapayipi lapho umthungo wokushisela izinqe zensimbi uthunga kanye namajoyinti amise okuka-D aphambana nama-spiral welding seams ahlolwa ngomabonakude we-X-ray noma ukuqoshwa.

(13) Ipayipi ngalinye lensimbi lihlolwa ingcindezi ye-hydrostatic, futhi ingcindezi ithatha uphawu lwe-radial. Ingcindezi yokuhlola nesikhathi kulawulwa ngokuqinile ipayipi lensimbi le-hydraulic microcomputer idivayisi yokubona. Imingcele yokuhlola iphrintwa futhi irekhodwe ngokuzenzakalelayo.

(14) Ukwenza imishini yokuphela kwepayipi, ukuze ukuma kobuso bokuphela, i-engeli ye-bevel kanye nonqenqema oluyi-obtuse kulawulwe ngokunembile.

Ipayipi lensimbi elishiselwe i-Spiral seam elingaphansi kwe-arc (SY5036-83) lokuthutha uketshezi olunengcindezi lisetshenziselwa ikakhulukazi amapayipi okuthutha uwoyela negesi yemvelo; ipayipi elishiselwe i-spiral seam high-frequency welded steel (SY5038-83) yokuthutha uketshezi oluthwala ingcindezi, kusetshenziswa indlela yokushisela ye-high-frequency lap Welding, umthungo ovunguzayo wepayipi wensimbi oshiselwe imvamisa ephezulu wokuthutha uketshezi olunomfutho. Ipayipi lensimbi linomthamo oqinile wokuthwala ingcindezi kanye nepulasitiki enhle, elungele ukushisela nokucubungula. Ngokuvamile, uthungelwano oluvunguzayo olungaphansi kwamanzi lwe-arc olushiselwe ipayipi lensimbi (SY5037-83) lokuthuthwa koketshezi olunomfutho ophansi lwenziwa ngokushisela okuzenzakalelayo okungaphansi kwe-arc okunezinhlangothi ezimbili noma ukushisela okunohlangothi olulodwa lwamanzi, ipayipi lensimbi elifakwe ngaphansi kwe-arc elishiselwe ukudlulisa uketshezi oluvamile lwengcindezi ephansi. njengegesi, umoya nesitimu