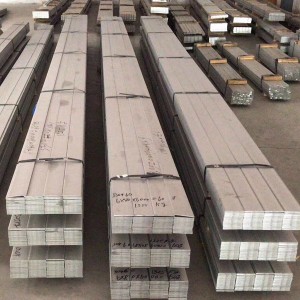

Spring Flat Steel

1. Ukwenza insimbi eyisicaba ngesiguquli kusebenzisa insimbi encibilikisiwe njengempahla eluhlaza. Kunezinto ezimbalwa eziyingozi ensimbi encibilikisiwe, futhi ikhwalithi yensimbi eyisicaba ekhiqizwayo iqinisekisiwe.

2. Ngenxa yesivuno esikhulu kanye nokusetshenziswa kwamandla aphansi, izindleko ngethani ngalinye ziphansi kunezomlilo kagesi.

3. Insimbi encibilikisiwe iphonswa ngokuqondile ku-billet, eshiya inqubo yokuvula i-billet futhi inciphisa izindleko.

4. I-billet eqhubekayo yokusakaza inezinga eliphezulu lokulinganisa, elingaqinisekisa izinga lokulinganisa lensimbi eyisicaba futhi lihlangabezane nezidingo zabasebenzisi.

Izinsimbi ezisansimbi, insimbi nezinsimbi ezingenayo insimbi

Ngaphambi kokwethula ukuhlukaniswa kwensimbi, thula kafushane imiqondo eyisisekelo yezinsimbi ezisansimbi, insimbi nezinsimbi ezingenayo insimbi.

1. Izinsimbi ezisansimbi zibhekisela kuma-aloyi ensimbi nensimbi. Okufana nensimbi, i-iron yengulube, i-ferroalloy, i-cast iron, njll. Insimbi ne-pig iron ama-alloys asekelwe ku-iron kanye ne-carbon njengento eyinhloko eyengeziwe, ebizwa ngokuthi ama-alloys e-iron carbon.

I-pig iron iwumkhiqizo wokuncibilikisa insimbi yensimbi ibe isithando somlilo esiqhumayo, esetshenziselwa kakhulu ukwenza insimbi nokuphonsa. I-cast pig iron iyancibilika esithandweni esincibilikisa insimbi ukuze kutholakale insimbi ewuketshezi (uketshezi). Insimbi ewuketshezi iphonswa ekubunjweni. Lolu hlobo lwensimbi lubizwa nge-cast iron. I-Ferroalloy iyingxubevange eyakhiwe ngensimbi ne-silicon, i-manganese, i-chromium, i-titanium nezinye izakhi. I-Ferroalloy ingenye yezinto zokusetshenziswa zokwenza insimbi. Isetshenziswa njenge-deoxidizer kanye nesengezo se-alloy element yensimbi ngesikhathi sokwenza insimbi.

2. Insimbi itholakala ngokuncibilikisa insimbi yengulube ukuze kwenziwe insimbi esithandweni sokwenza insimbi ngokwenqubo ethile.

3. Izinsimbi ezingenayo, ezaziwa nangokuthi izinsimbi ezingezona ayoni, zibhekisela ezinsimbi nama-alloys ngaphandle kwensimbi eyinsimbi, njengethusi, ithini, umthofu, i-zinc, i-aluminium, ithusi, ithusi, i-aluminium ingxubevange ne-bearing alloy. Ngaphezu kwalokho, i-chromium, i-nickel, i-manganese, i-molybdenum, i-cobalt, i-vanadium, i-tungsten ne-titanium nayo isetshenziswa embonini. Lezi zinsimbi zisetshenziswa kakhulu njengezithasiselo ze-alloy ukuthuthukisa ukusebenza kwezinsimbi. I-Tungsten, i-titanium ne-molybdenum isetshenziswa kakhulu ukukhiqiza i-carbide enosimende yamathuluzi okusika. Lezi zinsimbi ezingenayo insimbi zibizwa ngokuthi izinsimbi zezimboni. Ngaphezu kwalokho, kunezinsimbi eziyigugu: iplatinum, igolide, isiliva nezinsimbi ezingavamile, okuhlanganisa i-uranium enemisebe neradium.

Ukuhlukaniswa ngokusetshenziswa

(1) Insimbi yokwakha nobunjiniyela: insimbi evamile yesakhiwo sekhabhoni; Insimbi yesakhiwo se-alloy ephansi; Ukuqinisa insimbi.

(2) Insimbi yesakhiwo

Insimbi yokukhiqiza imishini: Insimbi yesakhiwo ecishiwe futhi epholile; Insimbi yesakhiwo eqinisa ubuso: okufaka insimbi eshisiwe, insimbi ye-ammoniated kanye nensimbi yokucisha indawo; Kulula ukusika insimbi yesakhiwo; Insimbi yokwenza ipulasitiki ebandayo: kufaka phakathi insimbi yokugxiviza okubandayo kanye nensimbi yesihloko esibandayo.

(1) Insimbi yokusebenza okukhethekile: Insimbi engagqwali ne-asidi; Insimbi ekwazi ukumelana nokushisa: okuhlanganisa insimbi ekwazi ukumelana ne-oxidation, insimbi yamandla okushisa nensimbi yevalvu yomoya; Insimbi yokushisa ingxubevange kagesi; Gqoka insimbi engazweli; Insimbi yokushisa ephansi; Insimbi kagesi.

(2) Insimbi yobungcweti: njengensimbi yebhuloho, insimbi yomkhumbi, insimbi yokubhayela, insimbi yomkhumbi wokucindezela, insimbi yemishini yezolimo, njll.