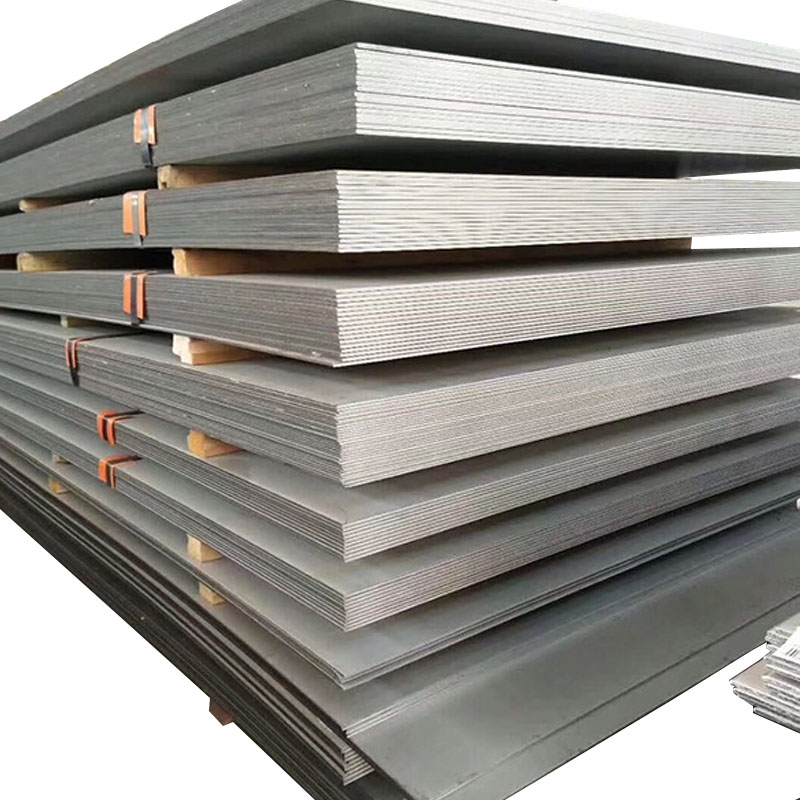

I-Stainless Steel Plate High Nickel Alloy 1.4876 Corrosion Resistant Alloy

I-1.4876 iyisixazululo esiqinile esisekelwe ku-Fe Ni Cr esiqinisiwe esonakele izinga lokushisa eliphezulu le-corrosion resistant alloy. Isetshenziswa ngaphansi kwe-1000 ℃. I-1.4876 i-corrosion resistant alloy inokumelana nokugqwala okuphezulu kakhulu kwezinga lokushisa kanye nokusebenza okuhle kwenqubo, ukuzinza okuhle kwe-microstructure, ukucubungula okuhle nokusebenza kokushisela. Kulula ukwakha ngokucubungula okubandayo nokushisayo. Ilungele ukwenza izingxenye ezidinga izinga lokushisa eliphezulu kanye nomsebenzi wesikhathi eside ngaphansi kwezimo ezimaphakathi ezicekela phansi.

I-1.4876 i-corrosion resistant alloy ine-stress corrosion crack resistance, i-stress corrosion crack resistance ku-chloride yamanzi, ukumelana nokugqwala ku-steam, ingxube yomoya kanye ne-carbon dioxide, kanye nokumelana nokugqwala okuhle kwama-asidi aphilayo njenge-HNO3, i-HCOOH, i-CH3COOH ne-propionic acid.

1.4876 amazinga aphezulu we-alloy ukumelana nokugqwala kukhona uchungechunge lwamazinga emazweni ahlukahlukene. Izindinganiso zakwamanye amazwe ngokuvamile ziyi-UNS, ASTM, AISI kanye ne-din, kuyilapho izindinganiso zethu kazwelonke zihlanganisa i-brand standard GB / t15007, rod standard GB / t15008, plate standard GB / t15009, pipe standard GB / t15011 kanye nebhande elijwayelekile le-GB / t15012.

Izinga lesiJalimane:1.4876, x10nicralti32-20, American Standard no8800, 1.4876, izinga likazwelonke gh1180, ns111, 0cr20ni32fe

I-Carbon C: ≤ 0.10, i-silicon Si: ≤ 1.0, i-manganese Mn: ≤ 1.50, i-chromium Cr: 19 ~ 23, i-nickel Ni: 30.0 ~ 35.0, i-aluminium al: ≤ 0.15 ~ 0.15 ~ 0.0: ≤ Titanium ithusi Cu: ≤ 0.75, phosphorus P: ≤ 0.030, isulfure s: ≤ 0.015, insimbi Fe: 0,15 ~ insalela.

I-1.4876 ingxube ye-corrosion resistant inokusebenza okuhle kokusebenza okushisayo. Izinga lokushisa elishisayo lokusebenza liyi-900 ~ 1200 futhi ukugoba okushisayo okwakhiwa yi-1000 ~ 1150 degrees. Ukuze wehlise ukugqwala kwe-intergranular corrosion ye-alloy, kufanele idlule endaweni yokuzwela engu-540 ~ 760 degree ngokushesha okukhulu. Ukuthambisa okuphakathi nendawo kuyadingeka ngesikhathi sokusebenza okubandayo. Izinga lokushisa lokushisa liyi-920 ~ 980. Izinga lokushisa eliqinile lesisombululo liyi-1150 ~ 1205. Isimo sokushisela sihle, kanye nendlela evamile yokushisela.

Ukuminyana: 8.0g/cm3, indawo encibilikayo: 1350 ~ 1400 ℃, amandla athile okushisa: 500J / kg. K, ukumelana: 0.93, i-elastic modulus: 200MPa.

I-alloy engu-1.4876 ekwazi ukumelana nokugqwala inokumelana nokugqwala kwengcindezi okuhle kakhulu emanzini aqukethe i-chloride ne-NaOH yokuhlushwa ephansi. Isetshenziswa kabanzi ukwenza imishini ekwazi ukumelana nokugqwala esikhundleni sensimbi eyi-18-8 austenitic. Isetshenziswa ku-evaporator yamanzi okucindezelayo, ukushisa okuphezulu kwegesi epholile, isishintshi sokushisa esipholile sesodium epholile kanye nepayipi lesitimu esishisa kakhulu embonini yamandla. Isetshenziswa ku-HNO3 epholile, ipayipi yokuqhekeka i-acetic anhydride kanye nemishini ehlukahlukene yokushintshanisa ukushisa embonini yamakhemikhali.