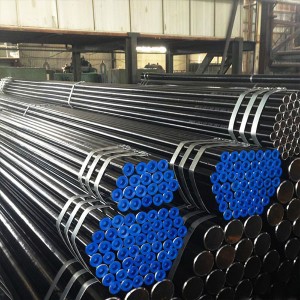

I-Thick Wall Alloy Tube

Amapayipi engxubevange anengxenye engenalutho futhi asetshenziswa ngobuningi njengamapayipi okudlulisa uketshezi, njengamapayipi okuthutha uwoyela, igesi yemvelo, igesi, amanzi kanye nezinto ezithile eziqinile. Uma kuqhathaniswa nensimbi eqinile njengensimbi eyindilinga, ipayipi lensimbi ye-alloy lilula uma ukugoba namandla e-torsion kufana. Ipayipi lensimbi ye-alloy iwuhlobo lwensimbi eyongayo, esetshenziswa kabanzi ekwenzeni izingxenye zesakhiwo kanye nezingxenye zemishini, njengamapayipi okubhola uwoyela kanye nokudluliswa kwezimoto. Izimbazo, amafreyimu amabhayisikili kanye nezikafula zensimbi ezisetshenziswa ekwakheni, njll. Ukusetshenziswa kwamapayipi ensimbi ye-alloy ukwenza izingxenye zamandandatho kungakhuphula izinga lokusebenzisa izinto ezisetshenziswayo, kube lula inqubo yokukhiqiza, konga izinto ezisetshenziswayo kanye nokucutshungulwa kwamahora abantu, njengokugingqa izindandatho. , imikhono kajack, njll, esetshenziswe kabanzi ekukhiqizeni amapayipi ensimbi. Amapayipi ensimbi ye-alloy nawo ayimpahla ebaluleke kakhulu yezikhali ezahlukahlukene ezijwayelekile. Imiphongolo yezibhamu nemiphongolo yonke yenziwe ngamapayipi ensimbi. Amapayipi ensimbi ye-alloy angahlukaniswa abe amapayipi ayindilinga kanye namapayipi amise okukhethekile ngokusho kobunjwa bendawo ehlukene. Njengoba indawo yesiyingi iyona enkulu kunazo zonke ngaphansi kwesimo somjikelezo olinganayo, uketshezi oluningi lungathuthwa ngeshubhu eliyindilinga. Ukwengeza, lapho ingxenye yendandatho ingaphansi kokucindezela kwe-radial yangaphakathi noma yangaphandle, amandla ayafana ngokuqhathaniswa. Ngakho-ke, iningi lamapayipi ensimbi angamapayipi ayindilinga.

Ukuhlukaniswa kwamapayipi alloy anezindonga eziwugqinsi

Inzuzo enkulu yamapayipi anezindonga eziwugqinsi ukuthi angasetshenziswa kabusha ngo-100%, okuhambisana nesu likazwelonke lokuvikela imvelo, ukonga ugesi, nokonga izinsiza. Umgomo kazwelonke ukhuthaza ukunwetshwa kwezindawo zokufaka izicelo zamapayipi anezindonga eziwugqinsi.

Ukubuka konke kwenqubo

Ukuginqika okushisayo (ithubhu lensimbi elingenamthungo elikhishiwe): ishubhu eliyindilinga → ukushisisa → ukubhoboza → ukugoqeka okuphambano kwama-roll amathathu, ukugoqeka okuqhubekayo noma ukukhishwa → ukususwa kweshubhu → ukusika (noma ukunciphisa) → ukupholisa → ishubhu le-billet → ukuqondisa → Ukuhlolwa kokucindezela kwamanzi (noma iphutha ukutholwa) → maka → indawo yokugcina impahla.

Ipayipi lensimbi elibandayo elidonsayo (eligoqiwe) elingenamthungo: ishubhu eliyindilinga billet → ukushisisa → ukubhoboza → isihloko → annealing → pickling → ukugcoba (i-copper plating) → umdwebo obandayo onamaphase amaningi (ukugoqeka okubandayo) → ishubhu le-billet → ukwelashwa kokushisa → ukuqondisa → Ukuhlolwa kwengcindezi yamanzi (ukutholwa kwamaphutha) → maka → indawo yokugcina impahla.

1XXX uchungechunge lwe-alloy olusekelwe ku-aluminium emsulwa.

2XXX Ingxubevange ye-Aluminiyamu nethusi njengengxenye eyinhloko ehlanganisayo.

3XXX Ingxubevange ye-Aluminium ene-manganese njengengxenye eyinhloko ehlanganisayo.

Ukusetshenziswa kweshubhu ye-Titanium alloy: I-Titanium alloy tube isetshenziswa kakhulu kwezokundiza. Iwuhlobo lweshubhu ye-alloy esetshenziselwa ngokukhethekile ukuhamba kwezindiza ezinobunzima obuphezulu kanye nokumelana nokushisa okuphezulu.

4XXX Ingxubevange ye-Aluminium ene-silicon njengengxenye eyinhloko ehlanganisayo.

5XXX Ingxubevange ye-Aluminium ene-magnesium njengengxenye eyinhloko yengxubevange.

6XXX Ingxubevange ye-Aluminiyamu ene-magnesium ne-silicon njengezici eziyinhloko zengxubevange.

7XXX Ingxubevange ye-Aluminium ene-zinc njengengxenye eyinhloko ehlanganisayo.

Ifomula yesisindo se-alloy tube:[(ukujiya kodonga lwangaphandle)*ukujiya kodonga]*0.02483=kg/m (isisindo imitha)