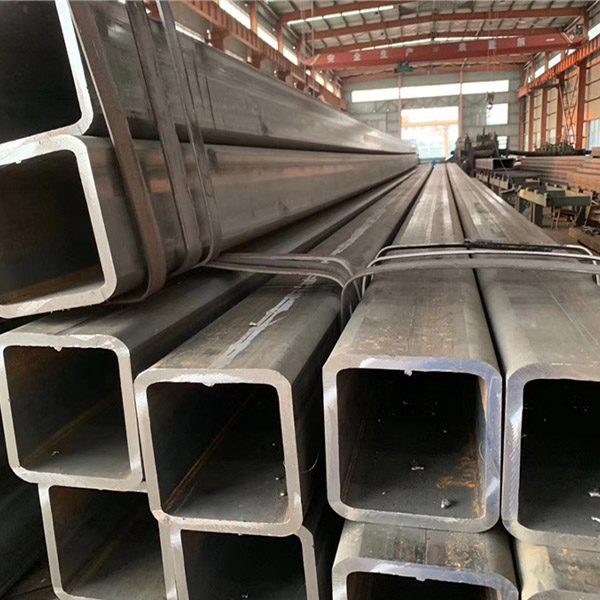

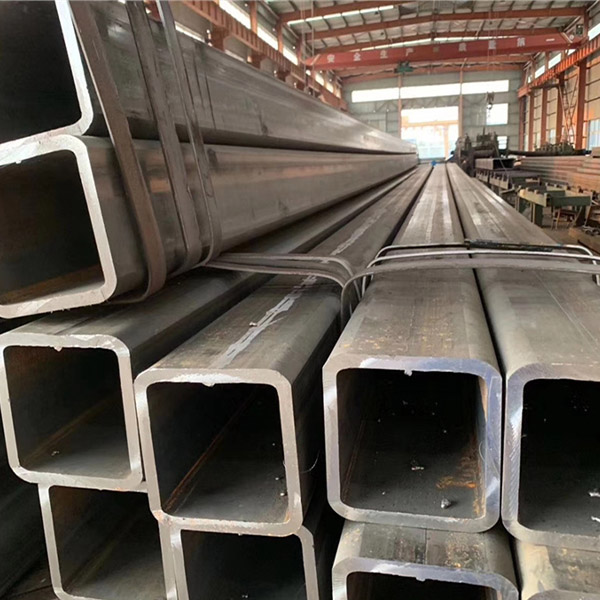

I-Seamless Square Tube

Isicelo: i-fluid tube, i-boiler tube, ishubhu yesakhiwo

I-alloyed noma cha: Ayinangxube

Umumo wesigaba: isikwele

Ishubhu elikhethekile: ishubhu elinezindonga eziwugqinsi

Ubukhulu: 140

Okujwayelekile: ASTM

Ubude: 12M, 6m, 6.4M, 1-12m

Isitifiketi: ISO9001

Ibanga: I-Carbon Steel

Ukwelashwa kwendawo: ukugoqa okushisayo

Ukubekezelela: ±1%

Izinsizakalo zokucubungula: ukushisela, ukubhoboza, ukusika, ukugoba

Igama elingukhiye: ishubhu eligoqiwe elishisayo

Inani elincane le-oda: 1 ton

Inhloso: Isakhiwo sokwakha

Isimo: isikwele.

Unxande. Umjikelezo

Umbala: umbala wemvelo

Ukupakisha: izinga lokufaneleka emoyeni

Inqubo yokupakisha: yamukela ukukhiqizwa okwenziwe ngezifiso

Kuya ngosayizi: usayizi owenziwe ngezifiso

Ikhono Lokuhlinzeka: amathani ayi-15,000/ton wamapayipi ensimbi yesikwele ngenyanga

Imininingwane yokupakisha: ukupakisha okujwayelekile kokuthumela noma ngokuya ngezidingo zekhasimende.

Itheku: China

Uma kuqhathaniswa nensimbi eqinile njengensimbi eyindilinga, ipayipi lensimbi ngokuvamile lilula uma ukugoba namandla e-torsion kufana. Iwuhlobo lwensimbi eyongayo enezingxenye eziphambanayo, esetshenziswa kakhulu ekwenzeni izingxenye zesakhiwo nezingxenye eziwumshini, njengamapayipi okubhola uwoyela, amashafu okuhambisa izimoto, amarack ebhayisikili kanye nezikafula zensimbi ezisetshenziswa ekwakheni. Ukusetshenziswa kwamapayipi ensimbi ukuze kukhiqizwe izingxenye ezimise okwendandatho kungakhuphula izinga lokusetshenziswa kwezinto, kwenze inqubo yokukhiqiza ibe lula, futhi konge izinto zokwakha kanye namahora okusebenza, njengamaringi aginqikayo, imikhono kajack, njll. Yenziwe ngensimbi. amapayipi ngo-2013. Amapayipi ensimbi nawo ayinto ebaluleke kakhulu yezikhali ezihlukahlukene ezivamile kanye nemishini yezempi. Imiphongolo yezibhamu nemiphongolo yonke yenziwe ngamapayipi ensimbi. Amapayipi ensimbi angahlukaniswa abe amapayipi ayindilinga kanye namapayipi amise okwesipesheli ngokuya ngobumo bendawo ephambanayo. Ngenxa yesimo se-circumference elinganayo, uketshezi oluningi lungathuthwa ngeshubhu eliyindilinga. Uma ingxenye yendandatho ingaphansi kwengcindezi ye-radial yangaphakathi noma yangaphandle, amandla ayafana, futhi iningi lamapayipi ensimbi amapayipi ayindilinga.

1. Ipulasitiki

I-Plasticity ibhekisela ekhonweni lezinto zensimbi ukukhiqiza ukuguqulwa kwepulasitiki (ukuguqulwa okuhlala njalo) ngaphandle kokulimala ngaphansi komthwalo.

2. Ubulukhuni

Ukuqina kuyisilinganiso sokuqina kwezinto zensimbi. Indlela evame ukusetshenziswa kakhulu yokulinganisa ubulukhuni kulokhu kukhiqizwa yindlela yobulukhuni bokungena, esebenzisa i-indenter ethile yejiyomethri ukuze icindezele ebusweni bensimbi ukuze ihlolwe ngaphansi komthwalo othile, futhi ukubaluleka kokuqina kunqunywa ngokwezinga. yokuhlehlisa.

Izindlela ezivame ukusetshenziswa zihlanganisa ukuqina kwe-Brinell (HB), ukuqina kwe-Rockwell (HRA, HRB, HRC) kanye nokuqina kwe-Vickers (HV).

3. Ukukhathala

Amandla, ipulasitiki, nobulukhuni zonke ziyizinkomba zezakhiwo zemishini yensimbi ngaphansi komthwalo omile. Eqinisweni, izingxenye eziningi zomshini zisebenza ngaphansi kwemithwalo ye-cyclic, ngaphansi kwalesi simo izingxenye zizokhathala. Amapayipi ensimbi anomumo okhethekile anamanye ama-cross-sectional shapes nawo ayadingeka.

Ipayipi elishiselwe lensimbi lokuthutha uketshezi olunengcindezi ephansi (GB/T3092-1993) libizwa nangokuthi ipayipi elishiselwe elijwayelekile, elivame ukubizwa nge-clarinet. Kuyipayipi elishiselwe insimbi elisetshenziselwa ukudlulisa amanzi, igesi, umoya, uwoyela nesitimu sokushisisa kanye nolunye uketshezi olunomfutho ophansi kanye nezinye izinjongo. Ugqinsi lwamapayipi ensimbi luhlukaniswe ngamapayipi ensimbi ajwayelekile kanye namapayipi ensimbi ajiyile; amafomu okuphela kokuxhumana ahlukaniswe ngamapayipi ensimbi angenantambo (amapayipi abushelelezi) namapayipi ensimbi anentambo. Ukucaciswa kwepayipi yensimbi kuvezwa ububanzi obujwayelekile (mm), okuyinani elilinganiselwe lobubanzi obungaphakathi. Kuwumkhuba ukuveza ngamasentimitha, njengokuthi 11/2. Amapayipi ensimbi ashiselwe okuthutha uketshezi olunomfutho ophansi awasetshenziselwa ukuthutha uketshezi kuphela, kodwa futhi asetshenziswa njengamapayipi asekuqaleni amapayipi ensimbi ashiselwe ukuthutha uketshezi olunomfutho ophansi.

Ipayipi lensimbi eliphekiweyo elishiselwe ukuthutha uketshezi olunengcindezi ephansi (GB/T3091-1993) liphinde libizwe ngokuthi ipayipi lensimbi eliphehliwe, elivame ukubizwa ngokuthi ipayipi elimhlophe. Ipayipi lensimbi elinediphu elishisayo elishiselwe (isithando somlilo elishiselwe noma elishiselwe ngogesi) elisetshenziselwa ukuhambisa amanzi, igesi, uwoyela womoya, ukushisisa isitimu, amanzi afudumele kanye nolunye uketshezi olunomfutho ophansi noma ezinye izinjongo. Ukuqina kodonga lwepayipi lensimbi kuhlukaniswe ipayipi elivamile lensimbi kanye nepayipi eliwugqinsi lensimbi; uhlobo lokuphela koxhumano luhlukaniswe ngepayipi lensimbi elingafakwa ngemicu kanye nepayipi lensimbi elinentambo.

I-Ordinary carbon steel wire casing (GB3640-88) iyipayipi lensimbi elisetshenziselwa ukuvikela izintambo kumaphrojekthi okufakwa kukagesi afana nokwakhiwa kwezimboni nokwakhiwa kanye nokufakwa kwemishini nemishini.

Umthungo oqondile wepayipi wensimbi kagesi oshiselwe (YB242-63) iyipayipi lensimbi elinomthungo wokushisela ohambisana nendawo yobude yepayipi lensimbi. Imvamisa ihlukaniswe ngamapayipi ensimbi kagesi ashiselwe kagesi, ipayipi elicijile elinezindonga ezincane, ipayipi likawoyela lokupholisa i-transformer njalonjalo.

Ipayipi lensimbi elinomthungo ovunguzayo elingaphansi kwe-arc elishiselwe (SY5036-83) lokuthuthwa koketshezi oluthwala ingcindezi luwumugqa wensimbi ogoqelwe oshisayo njengeshubhu elingenalutho, elakheke ngokuvunguza ekushiseni okujwayelekile bese lishiselwa yi-arc engaphansi kwezinhlangothi ezimbili. Isetshenziselwa umthungo ovunguzayo wokuthutha uketshezi olunengcindezi. Ipayipi Lensimbi. Ipayipi lensimbi linomthamo oqinile wokuthwala ingcindezi nokusebenza okuhle kwe-welding. Ngemuva kokuhlolwa okuqinile okunhlobonhlobo kwesayensi nokuhlolwa, kuphephile futhi kuthembekile ukusetshenziswa. Ipayipi lensimbi linobubanzi obukhulu, ukusebenza kahle kokudlulisa okuphezulu, futhi lingasindisa utshalomali ekubekeni amapayipi. Isetshenziswa kakhulu kumapayipi okuthutha uwoyela negesi yemvelo.

| Isevisi yokucubungula | Ukugoba, ukushisela, ukuqaqa |

| Igcotshwe ngamafutha noma i-noiled | Awekho amafutha |

| Igama lomkhiqizo | Ipayipi lepulasitiki elifakwe ngaphakathi |

| I-Moq | 1 ton |

| Amagama ayisihluthulelo | Kufakwe ipayipi lensimbi engagqwali |

| Ubuso | Isicelo sekhasimende |

| Isimo | Ishubhu yesikwele |

| Isikhathi sokuthumela | Phakathi kwezinsuku ezingu-7-15 |

| Okujwayelekile | Gb 5310-1995 |

Indlela yokuxhuma ipayipi lensimbi: intambo, ishiselwe.

Ukuxhumana kwe-groove

(1) Ukuqhekeka kwe-roll groove weld

1. Hlelisa izimbambo zokushisela odongeni lwangaphakathi lwengxenye ye-pressure groove yenozzle ukuze unciphise ukumelana komsele.

2, Lungisa i-axis yepayipi lensimbi kanye nemishini yokugenca, futhi udinga ipayipi lensimbi kanye nemishini yokugenca ukuze kube izinga.

3. Lungisa isivinini sokucindezela i-groove, futhi isikhathi sokwenza i-groove asikwazi ukudlula umgomo, sebenzisa amandla ngokulinganayo futhi kancane kancane.

(2) Ukuphuka kwepayipi lensimbi le-groove

1. Hlelisa izimbambo zokushisela ezingaphakathi zodonga lwengxenye yomlomo wepayipi ukuze unciphise ukumelana komsele.

2, Lungisa i-axis yepayipi lensimbi kanye nemishini yokugenca, edinga ipayipi lensimbi kanye nemishini yokugoqa ukuze kube izinga.

3. Lungisa isivinini sokucindezela, isivinini sokucindezela asikwazi ukweqa okubekiwe, sebenzisa amandla ngokulinganayo futhi kancane.

4. Hlola ububanzi nemodeli yerola esekelayo kanye ne-pressure roller ye-rolling groove, futhi uhlole ukuthi akukho yini ukungafani kusayizi wamarola amabili, okungase kubangele ukubanjwa.

5. Sebenzisa i-vernier caliper ukuze uhlole ukuthi i-groove yepayipi yensimbi icacisiwe.

(3) I-groove eyakhiwe umshini we-groove rolling kufanele ihlangabezane nezimfuneko ezilandelayo

I-1, Indawo yokuphela kwepayipi engxenyeni ye-groove kufanele ibe bushelelezi futhi ingabi nokungalingani kanye nama-roll marks.

2, Isikhungo se-groove kufanele sigxile ngodonga lwamapayipi, ububanzi nokujula kwe-groove kufanele kuhlangabezane nezidingo, futhi uhlole ukuthi uhlobo lwengxenye ye-clamp lulungile.

3. Gcoba okokuthambisa iringi yokuvala irabha bese uhlola ukuthi iringi yokuvala irabha yonakele yini. I-lubricant akumele ibe yinto yokuthambisa kawoyela.

Uxhumano olushiselwe

1. Umlomo wepayipi wepayipi yensimbi yama-galvanized awukho emgqeni oqondile futhi kunenkinga yomlomo we-oblique wepayipi yensimbi ngemva kokubhoboza. Kunconywa ukusika ikhanda lepayipi isikhathi esifushane ngaphambi kokucubungula.

I-2, Ngemva kokuba imibhobho yamapayipi ensimbi enezinsimbi ixhunyiwe, ama-nozzles amabili awaxhunyiwe ngokuqinile, okuholela ekugqileni okungalingani kokuhlangene okuhlanganisiwe; futhi ipayipi i-elliptical ngenxa yezizathu zayo noma ama-bumps ezokuthutha. Kunconywa ukusika ikhanda lepayipi isikhathi esifushane. Lungisa futhi.

3. Ngemva kokuba imibhobho yamapayipi ensimbi ebilisiwe, kuvela amabhamuza emibhobolweni:

4. Ngenxa yezizathu zobuchwepheshe ngesikhathi sokushisela.

5. Kunamaqhuqhuva e-zinc ku-nozzle, angabangela ubunzima bokushisela namabhamuza. Uma amaqhuqhuva e-zinc emakhulu kakhulu futhi amapayipi amaningi kakhulu, izigaxana ezilula ze-zinc kufanele zisuswe.

Uxhumano lwezintambo

1, Ibhande elinentambo: Ihupho yepayipi kanye nebhande elinentambo akukwazi ukuthintwa ngokuphelele, kuxegiswe, kunqamule ingxenye yebhakede engahleliwe, bese uphinda ufake intambo.

2. Intambo yepayipi yensimbi kanye nentambo ye-hoop yepayipi ayifani futhi ayikwazi ukuxhunywa. Ihupho yepayipi kufanele ishintshwe noma okokusebenza kufanele kulungiswe futhi kucushwe kabusha.

3. Ukuphrinta okungekho ngemva kokucutshungulwa kwepayipi lensimbi: Linganisa ukuthi ubukhulu bodonga lwepayipi lensimbi bungahlangabezana yini nezidingo zokujiya ezijwayelekile zepayipi elinentambo